|

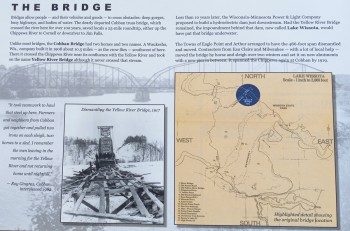

The Cobban Bridge

The original Cobban Bridge was brought up from

the Yellow River by Chippewa Falls in the winter

by the owner of the The original Cobban Bridge was brought up from

the Yellow River by Chippewa Falls in the winter

by the owner of the store to replace his ferry system with a more

efficient method of river crossing. This was accomplished before the

hydroelectric power dams

were built in Jim Falls and Chippewa Falls creating Lake Wissota in the early 1900's. The Bridge

was partially dismantled in Chippewa and was

pulled by teams of horses up the frozen river from Chippewa Falls on sleds (then called

Chippewa Junction) to Cobban. Amazing courage of the individuals that

make up this era. Imagine the mess if the bridge sections would have fallen through thin ice. The

positioning of the old Chippewa Bridge at Cobban over the Chippewa River allowed

customers to cross the river and shop at the store or drop milk off without making a thirty mile round trip in either

direction if store to replace his ferry system with a more

efficient method of river crossing. This was accomplished before the

hydroelectric power dams

were built in Jim Falls and Chippewa Falls creating Lake Wissota in the early 1900's. The Bridge

was partially dismantled in Chippewa and was

pulled by teams of horses up the frozen river from Chippewa Falls on sleds (then called

Chippewa Junction) to Cobban. Amazing courage of the individuals that

make up this era. Imagine the mess if the bridge sections would have fallen through thin ice. The

positioning of the old Chippewa Bridge at Cobban over the Chippewa River allowed

customers to cross the river and shop at the store or drop milk off without making a thirty mile round trip in either

direction if  they chose to not take the ferry. As they chose to not take the ferry. As the 70 ton capacity

bridge was in the final stages of set-up, Gottlieb Gerber and a few

others took a half barn door and painted on it "LOAD LIMIT FIVE

TONS" and hung it on the East end of the bridge. This was intended

as a joke and it stayed there until the some time in the 1940's. This

could be the beginning to the status of the bridge as a limit of

5 tons. This old girder bridge stood functionally until 2017 when an inspection deemed it to be unsafe. The bridge had one lane traffic, with hardwood cross-plank roadbed

with additional hardwood planks for the tire paths. As you walk or ride over on a bike, you can see

the water beneath through the gaps in the wooden planks. The replacement bridge was opened in 2023 with a ribbon cutting ceremony. The next bridge to the south was in Chippewa Falls or to the north was Cornell, depending on which direction

you wished to travel. the 70 ton capacity

bridge was in the final stages of set-up, Gottlieb Gerber and a few

others took a half barn door and painted on it "LOAD LIMIT FIVE

TONS" and hung it on the East end of the bridge. This was intended

as a joke and it stayed there until the some time in the 1940's. This

could be the beginning to the status of the bridge as a limit of

5 tons. This old girder bridge stood functionally until 2017 when an inspection deemed it to be unsafe. The bridge had one lane traffic, with hardwood cross-plank roadbed

with additional hardwood planks for the tire paths. As you walk or ride over on a bike, you can see

the water beneath through the gaps in the wooden planks. The replacement bridge was opened in 2023 with a ribbon cutting ceremony. The next bridge to the south was in Chippewa Falls or to the north was Cornell, depending on which direction

you wished to travel.

|

|

Cobban Floods

A few floods over the last century

claimed much personal property, but the residents worked hard to keep

the community together. The picture at the left shows the Omaha

tracks under water during the flood of 1941. To the right side of the

tracks, the Cobban store can be seen. The depot is to the left almost directly

across the tracks from the white Cobban store. The lumber mill can be

seen as the larger building to the far right near the top. A few floods over the last century

claimed much personal property, but the residents worked hard to keep

the community together. The picture at the left shows the Omaha

tracks under water during the flood of 1941. To the right side of the

tracks, the Cobban store can be seen. The depot is to the left almost directly

across the tracks from the white Cobban store. The lumber mill can be

seen as the larger building to the far right near the top.

|

|

The Cheese Factory

The

second Cheese Factory being built in Cobban in 1916 by the Shultz

Brothers. The building

stands today surviving many floods and time. Picture on left reflects 1916

while picture on right reflects nearly 90 years later. Milk was brought

in by the local farmers to be sold to the factory. Butter fat from

the milk was used to make cheese and other dairy products. The Factory

was a source of income for the dairy farmers as well as the employees of

the factory. The

second Cheese Factory being built in Cobban in 1916 by the Shultz

Brothers. The building

stands today surviving many floods and time. Picture on left reflects 1916

while picture on right reflects nearly 90 years later. Milk was brought

in by the local farmers to be sold to the factory. Butter fat from

the milk was used to make cheese and other dairy products. The Factory

was a source of income for the dairy farmers as well as the employees of

the factory.

|

|

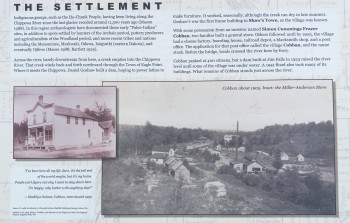

Cobban Store

The

second Cobban Store was rebuilt in 1923. It looked much like the first

one (shown on left) that was severely damaged in a flood in 1922. To the

right of the second store build was a weigh scale used for weighing

entire wagons of produce as they arrived for export. Sugar Beets and

potatoes were a common commodity for the Cobban area. The

second Cobban Store was rebuilt in 1923. It looked much like the first

one (shown on left) that was severely damaged in a flood in 1922. To the

right of the second store build was a weigh scale used for weighing

entire wagons of produce as they arrived for export. Sugar Beets and

potatoes were a common commodity for the Cobban area.

|

|

Cobban Depot

Cobban

Depot was used for passenger service as well as processing the merchandise

that left and entered the Cobban Community. The Cobban

Depot was used for passenger service as well as processing the merchandise

that left and entered the Cobban Community. The siding near the

station was tended by Emmett Yeager. He used a small white horse to

position railroad cars so the could be loaded or unloaded. The cars

would

then be staged for pick-up by the Omaha as it came through on it's

scheduled stop. They would hitch the horse to the car and the horse

would lean into the traces (sometimes called tugs) and it would stay

leaning until the car began to move. Sometimes the

motion was started by a man with a tool called a "Johnson Bar"

by prying it under the wheel of the car. As it began to move the horse

would take bigger steps until the car was "spotted", then someone

would set the hand brake on the car. The horses job was then done until

siding near the

station was tended by Emmett Yeager. He used a small white horse to

position railroad cars so the could be loaded or unloaded. The cars

would

then be staged for pick-up by the Omaha as it came through on it's

scheduled stop. They would hitch the horse to the car and the horse

would lean into the traces (sometimes called tugs) and it would stay

leaning until the car began to move. Sometimes the

motion was started by a man with a tool called a "Johnson Bar"

by prying it under the wheel of the car. As it began to move the horse

would take bigger steps until the car was "spotted", then someone

would set the hand brake on the car. The horses job was then done until  the next car needed to be moved. The depot has been gone since shortly

after the flood of 1941.

the next car needed to be moved. The depot has been gone since shortly

after the flood of 1941.

|

|

Lumber and Shingle Mill

Lumber

was an export from Cobban area. Many trees were transformed into

building material for area communities as well as residents of the

Cobban community. Shown at the left are stacks of lumber set to dry so

it can be used without warping after construction. Seasoned lumber was a

commodity that came from the "Big Mill" that kept Cobban

flourishing as long as it lasted. When the area became "logged

out" the lumber mill vanished as did much of the town. Lumber

was an export from Cobban area. Many trees were transformed into

building material for area communities as well as residents of the

Cobban community. Shown at the left are stacks of lumber set to dry so

it can be used without warping after construction. Seasoned lumber was a

commodity that came from the "Big Mill" that kept Cobban

flourishing as long as it lasted. When the area became "logged

out" the lumber mill vanished as did much of the town.

The Shingle Mill was originally owned by Stevens and

Jarvis Lumber Company of Eau Claire, Wisconsin and was later purchased

by Julius Miller who was part owner of the Cobban Store. The material

for manufacturing shingles came from around the Cobban area. There were

many logs lying in the woods that were either missed due to deep snow or

left to stay because of the red sawdust coming from the crosscut

saw. This would indicate that

the log might be getting soft inside. Only logs of solid stature

were accepted at saw mills years ago. Much of the lumber is made

today from what years ago was called

firewood. Also

material

for manufacturing shingles came from around the Cobban area. There were

many logs lying in the woods that were either missed due to deep snow or

left to stay because of the red sawdust coming from the crosscut

saw. This would indicate that

the log might be getting soft inside. Only logs of solid stature

were accepted at saw mills years ago. Much of the lumber is made

today from what years ago was called

firewood. Also  brought to the shingle mill was the tall stumps

that were still standing in the woods. Lumbermen would cut high to avoid

hollow bottoms in the trees. Another source of logs was called

"river pigs". These were logs that had been lodged in the

river bottom and long the sides of the river banks after log drives were

complete. The logs that were intended for shingles were cut into lengths

of 20 inches then fed through a horizontal saw, sorted, trimmed, and

bundled. brought to the shingle mill was the tall stumps

that were still standing in the woods. Lumbermen would cut high to avoid

hollow bottoms in the trees. Another source of logs was called

"river pigs". These were logs that had been lodged in the

river bottom and long the sides of the river banks after log drives were

complete. The logs that were intended for shingles were cut into lengths

of 20 inches then fed through a horizontal saw, sorted, trimmed, and

bundled.

|

|

Cobban Today

Cobban WI, viewed from across the

Chippewa river in the winter from the "River Road"

Highway 178 in 2017.

|

|

|

|

|

Directly South of Cobban is a small outlet

from the river that required a small bridge to cross the entrance. This

particular bridge used log piles driven into the river bed for support. |

A 1920's style farm house in the background

between Cobban and the railroad bridge. The depot was located in this area would have

been the "Milk Pick-up" point for rail transportation from the

farm to the dairy just a few miles South |

|

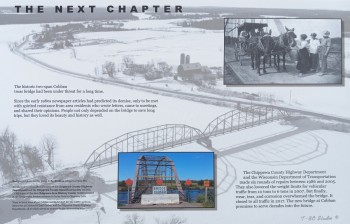

Cobban in 2025 reflects a new bridge has replaced the old truss bridge.

Across the Chippewa River signs have been placed reflecting the history of the truss bridge as reflected below

|

|

|

|

|

|

|