|

MISSOURI

PACIFIC EMD SD LOCOMOTIVES

|

|

The following

is reproduced from actual operating manuals

|

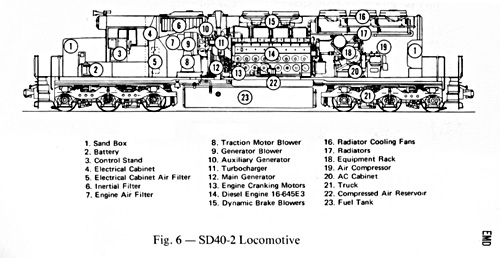

SD40

25 Units

Horsepower:

3000 Weight: 389,910 lbs.

Engine: 16-645E-3 V-Type Turbocharged

Fuel Capacity: 3,250 gals.

Gear Ratio: 62:15

Minimum Continuous Speed: 12.0 mph Cooling

Water Capacity: 254 gals. Tractive

Effort: 97,475 Sand Capacity:

56 cubic feet

Lube Oil Capacity: 243 gals.

SD40-2: 207

Units SD40-2c: 74 Units

Horsepower:

3000 Weight: 390,600 lbs.

Engine: 16-645E-3 V-Type Turbocharged

Fuel Capacity: 3,250 gals.

Gear Ratio: 62:15

Minimum Continuous Speed: 12.0 mph Cooling

Water Capacity: 275 gals. Tractive

Effort: 97,650 Sand Capacity:

56 cubic feet

Lube Oil Capacity: 243 gals.

SD50: 60

Units

Horsepower:

3600 Weight: 368,000 lbs.

Engine: 16-645F3B Turbocharged

Fuel Capacity: 4,500 gals.

Gear Ratio: 70:17

Minimum Continuous Speed: 12.0 mph Cooling

Water Capacity: 288 gals. Tractive

Effort: 91,980 Sand Capacity:

56 cubic feet

Lube Oil Capacity: 294 gals.

EMD CONTROL STANDS

Based on the EMD SD40 and SD40-2 model locomotives

|

|

|

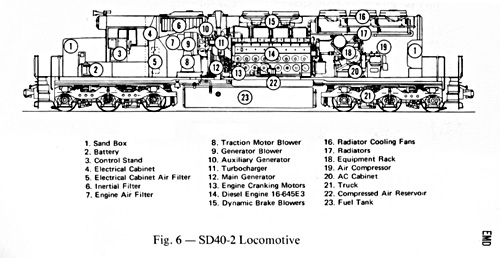

The EMD SD40 Control Stand

|

The AAR-EMD SD40-2 and SD50

Control Stand

|

The EMD Control Stand were equipped on NON

Dash-2 units such as the SD40s, GP35s and GP38s.

The Selector Lever has three

(3) positions which are # 1, OFF and B. The Selector Lever on the controlling

unit must be in the # 1 position for power, B position for dynamic braking

and OFF position when locomotive is parked. On trailing units, the lever

is always in the OFF position. This lever is spring loaded and returns

to center position after each movement. Its position is indicated by a

small illuminated window in the top left corner of the control stand.

A few units after June 1971 have three (3) position selector levers (PWR,

OFF, and B). The lever is placed in the PWR position for power, B for

dynamic braking, and OFF when locomotive is parked. On trailing units,

it is in the OFF position. The lever is NOT spring loaded and remains

in the position it was placed. Its position is indicated in an illuminated

window located directly above the selector lever.

The Reverse Lever has three

(3) positions which are Forward, Neutral and Reverse. The position of

the reverse lever on the controlling unit controls the direction of movement.

The reverse lever is removed from the control stand on trailing units

to lock the throttle and selector levers.

The Throttle Lever is used

for both power (when selector lever is in #1 position) and dynamic brake

(when selector lever is in B position). It has 10 positions: STOP, IDLE

and 1 thru 8.

The throttle is placed in the STOP position by pulling the throttle lever

outward (away from control stand) and moving it forward from IDLE to STOP.

This position shuts down all units in the consist except when isolation

switch of an individual unit is in START position.

The throttle placed in the IDLE position will be at idle engine speed

and power is not developed.

Positions 1 thru 8 power will increase the diesel engine speed and develop

a predetermined power output.

Using the dynamic braking is notchless on the throttle in runs 1 thru

8.

|

|

|

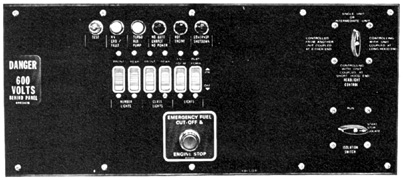

EMD NON Dash-2 Control Panel

|

EMD Dash-2 Control Panel

|

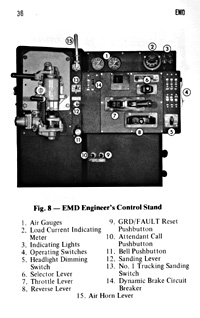

The AAR Standard Engineers Control Stand was used on ALL

of the EMD Dash-2 series locomotives, as well as on the GE Series-7 units.

This helped avoid confusion by having to learn several different types

of control stands for different models of locomotives. This control stand

was also installed on many of the older EMD units on major roads in the

late 1970s and early 1980s.

The Reverser Lever

has three positions: Forward, Neutral (center position) and reverse. The

position of the reverser lever on the controlling unit controls the direction

of movement (forward or reverse).

When the reverse lever is in neutral position, the throttle can be moved

into any position. The dynamic brake lever cannot be be moved from the

OFF position unless unless the reverse lever is in forward or reverse

position.

The reverser lever can be removed from the control stand when it is in

the neutral position. When removed, it locks both the throttle and dynamic

brake levers in idle and off positions. The reverser lever is to be removed

from the control stand on all trailing units in a locomotive consist.

The Throttle Lever has ten

positions: STOP, Idle, and Eight (8) power positions.

The throttle is placed in the STOP position by pulling the throttle lever

outward, away from the control stand, and moving it forward from idle

to stop. This position shuts down all units in the locomotive consist

except when the engine control switch is in START position.

The idle position allows the engine to run at idle speed, but no power

is developed.

Positions 1-8 will increase the engine speed. In each throttle position

a predetermined ampere output is developed.

The Dynamic Brake Lever has

three (3) positions: OFF, Set-up, and Braking Zone.

OFF is when the lever is placed in this position when dynamic brakes are

not being used.

Set-up establishes the dynamic braking circuits.

Braking Zone: This zone is numbered 1 to 8. The braking effort is increased

as the lever is advanced through the braking zone.

DYNAMIC BRAKES

Most of the Missouri Pacific locomotives did not have

dynamic brakes, however, there were some that did contain this feature

such as the SD40-2c (6000 Series Units) and some ex-Western Pacific units.

In addition, the Mo-Pac often used pool power from other roads, whose

power consisted of units with dynamic brakes. A brief explanation of the

varieties of dynamic brakes is listed here.

Standard Range Dynamic Brake

is the amount of retarding force developed as this brake increases with

the increase of the locomotive speed, reaching the maximum retarding force

at approximately 23 mph (with the 62:15 gear ratio). As speed increases

above 23 mph the retarding force will reduce gradually.

Extended Range Dynamic Brake provides maximum

retarding force in the entire speed range between 6 and 23 mph. This feature

works in conjunction with the Standard Range Dynamic Brake.

When an engineer changes operation from power to dynamic brake, he places

the throttle in the Idle position and must wait a minimum of 10 seconds

before applying the dynamic brake.

|

|

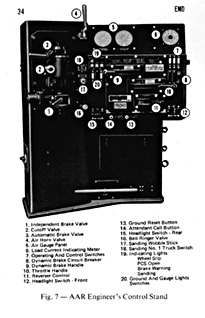

A Standard EMD SD40 Locomotive

|

|