Home

Corporate Induction

Track Design

|

Ultra Sonic Testing (UST)

Drax Power Station. This is a coal burning power station and has its own private sidings, for the delivery of coal by train. The tracks at the power station are tested for internal cracks and the only way to do this is by a method known as Ultra Sonic Testing (UST). UST works by sending out sound waves and bouncing them back off any surface they encounter. Sonar works on the same principle.

The principle of UST

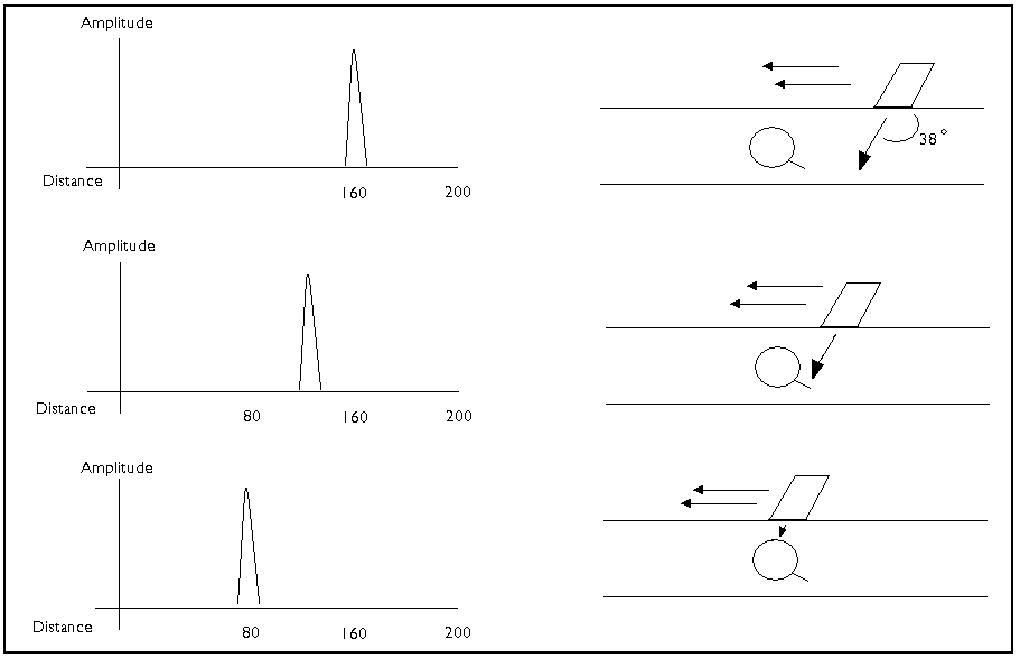

The reason for testing the rail at the power station was to check for internal flaws. As rail comes in standard lengths, it has to be joined together. This is done by one of two methods: welding or plating. When a standard piece of rail is manufactured, holes are made in each end of the section. This is to allow easy assembly when joining the rails with plates. It basically saves the drilling of bolt-holes while on site. It is these holes which are susceptible to cracking. Two types of crack can propagate from these holes; either horizontal cracks or angled cracks of approximately 45°. Since these cracks are internal and can be very fine (microns in width) UST has to be used in order to determine the condition of the joint and the rail.

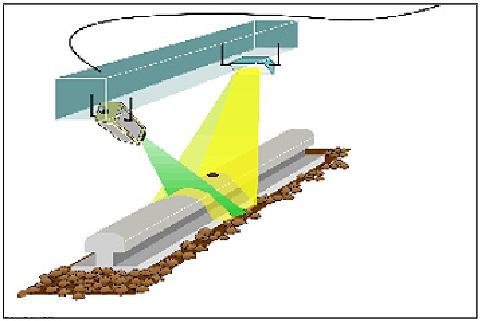

UST equipment and the scanning of the rail in progress

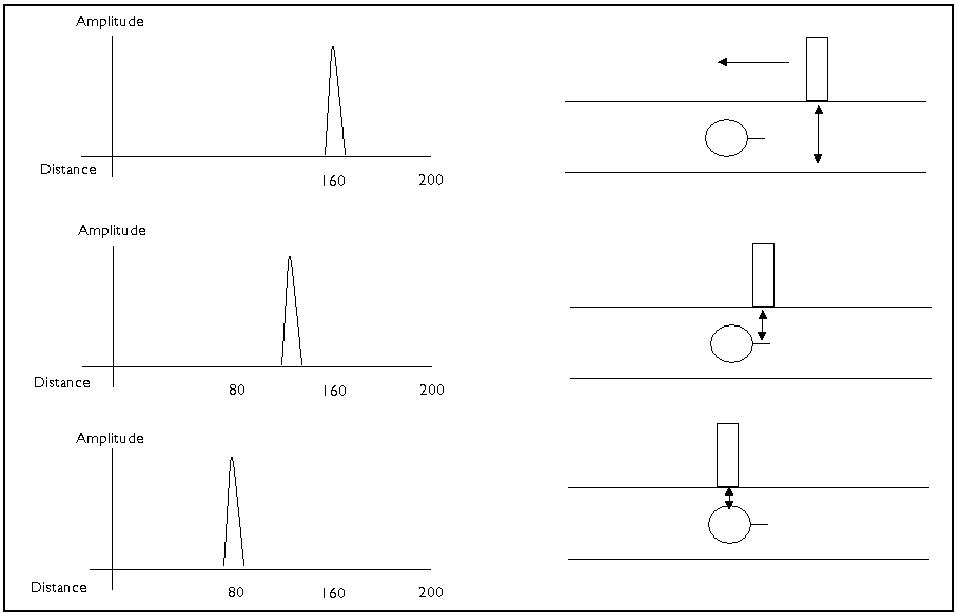

The process for scanning the rail was to firstly spray water over the joint. This is to reduce friction. The horizontal probe is then run over the head of the rail in both directions. Following this, the angled probe is run over the rail. Whilst the probes are in use, an oscilloscope readout is monitored by the user. This is in a graph format. The results look similar to those shown below.

The graphs seen on the oscilloscope show amplitude against distance in mm. That is, peaks are seen at 160 mm and 80 mm on vertical probes for non-effected rail. If a peak is seen between these distances, it is suspected that a crack is present, and the rail is usually replaced. The same applies for the angled probe. The only problem with this type of UST is that sometimes cracks can hide other, more serious cracks. That is, a more serious crack would be shadowed. Whilst out in Drax, we came across a piece of rail which is less than the minimum specifications. The line standards state that all pieces of jointed rail must be over 15 feet long. If a joint was to fail and the rail was less than 15 feet long, it can get caught up in the under carriage of the vehicle and cause even more damage. Since this was found on private sidings, the group and line standards do not apply, and the only action anyone can take is to inform the power station and recommend that they get this rectified. Some other parts of the rail were in poor condition. We noted some extreme lipping which is a result of much use. This indicates that too much wear has occurred and this rail needs to be replaced.

|

|||||||||