Home

The Railway Organisation

Track Design

|

Major Renewals

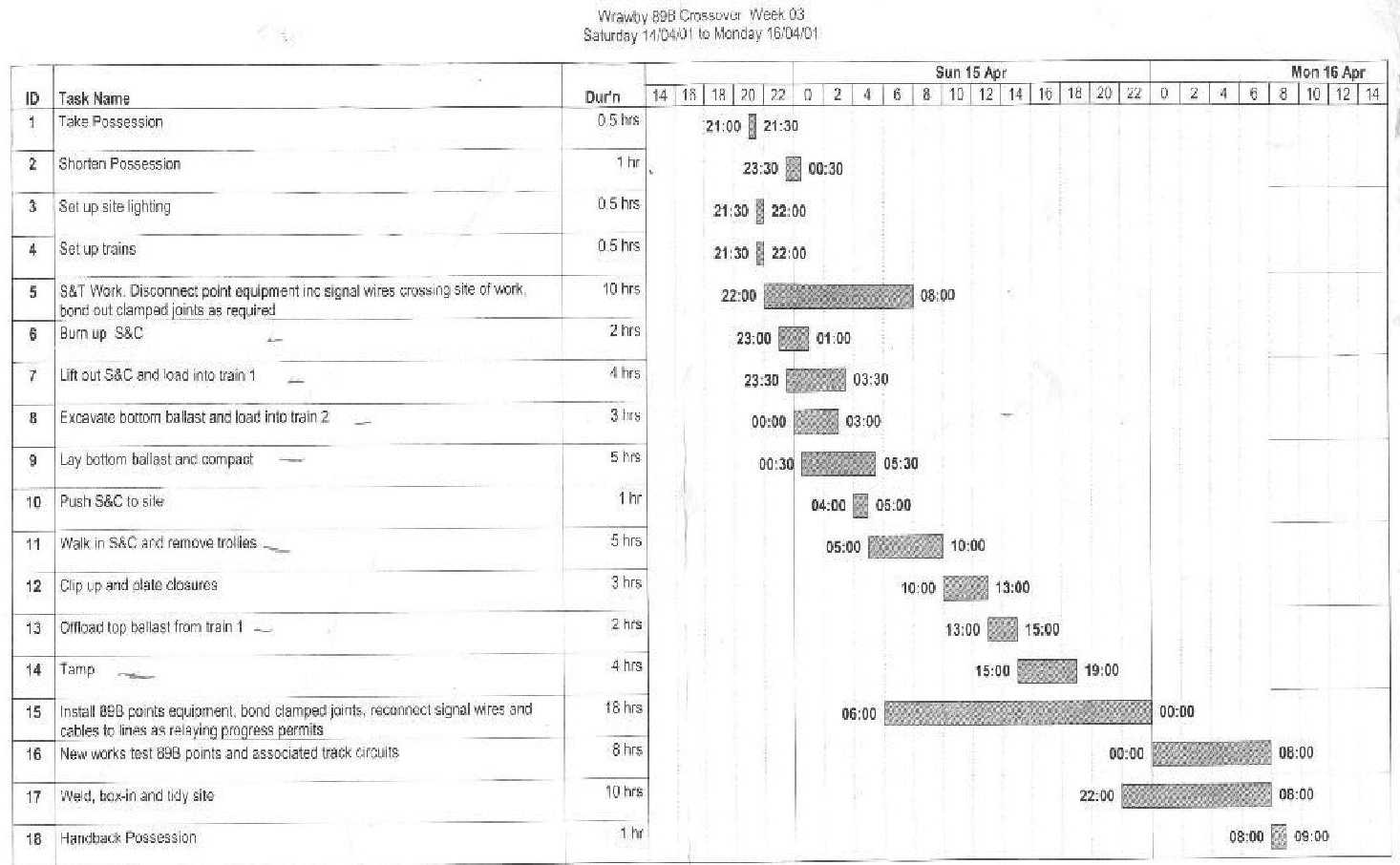

The process of carrying out renewal work generally follows a set pattern. This is decided at a site meeting, held a few days before the work is due to take place. All the relevant contractors attend the site meeting. A site meeting pack is handed out and this includes all kinds of information, such as planning times and relevant safety issues. Lets concentrate on a specific example. We will consider the Easter renewals weekend at Wrawby Junction, near Scunthorpe. This job took place during the Easter of 2001 and involved the renewal of some switches and crossings (S&C). A copy of the Gantt chart used for the planning can be seen below.

The process to the renewals work was as follows: Firstly, all equipment for the renewals work have to be delivered to site. That is, the sections of rail, sleepers, clips and other relevant equipment. Once delivered, usually a few days before the possession, the equipment is constructed. While the S&C is being built, the existing track is being prepared for removal. That is, removing fish plates found at the joints as well as unclipping and removing any cables and wires. Track walkers are used to lift and move entire sections of track. These can be seen below.

The track walkers pick up the section of rail, move side ways a few feet and then drop again. Pick up, move and drop. This process of moving the entire constructed section from the sidings to the rail is a very slow process. The track walkers work in a similar fashion the how a crab walks. Whilst the section of track is walked across to the existing rail, the existing track to be renewed is cut into pieces so that the cranes can come in and take it out of the ground.

Craning in action After the cranes have removed most of the old rail and sleepers, excavation begins. This is done by mechanical diggers; digging to about 1.5 metres. A sheet of material is placed on the ground, this being placed down to prevent material from working its way upwards to the track. This material is called Terratex Meanwhile the old S&C is loaded onto wagons while the new S&C is still being walked over to the track. A bottom layer of ballast is placed over the Terratex and the new section finally reaches the track. It is then dropped onto trolleys and pushed up to the point of insertion.

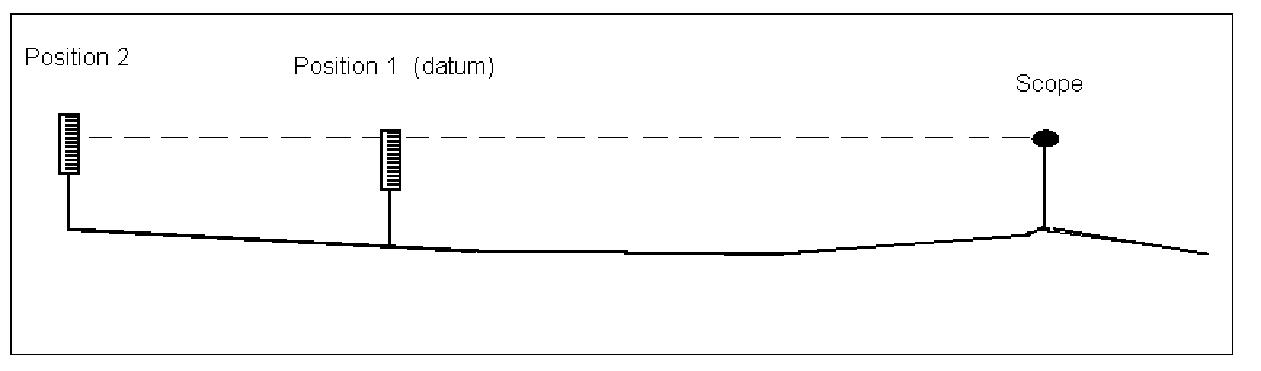

Trolleys to move the built up section along the track The new rail is dropped onto the layer of bottom ballast and is joined by either plating or welding to the existing railway. The next step is to drop the top layer of ballast onto the new rail. This is done by running some wagons over the new section which have channels underneath them. These are opened as the carriages pass over the section, and the ballast drops onto the track. This process has to be done carefully since problems can occur. At the renewals work I went to see, the ballast was dropped onto the new section unevenly. That is, one end of the new section had too much ballast while the opposite end had none whatsoever. Thais creates a problem for the tamper. As a result of this miscalculation, the ballast from the top heavy end had to be manually shovelled out, thus adding an extra two or three hours onto the job. Once the ballast was eventually levelled out across the whole new section, the new section has to be surveyed. That is, levels have to be identified so that the track can be hired or lowered by the tamper. The process of determining the track levels is done with what is effectively a telescope and a ruler. A measurement is taken at a datum level and all preceding positions are relative to the datum measurement.

Following this, markings are sprayed onto the track to indicate to the tamper operators how much to lift or lower the track. Also, the gauge is checked, and the relevant places are marked to tell the tamper operators if the track needs cables and points machines, the tamper is then ready to do its job. The tamper This is the process of moving the track into the correct position. This can be done horizontally (left and right, or otherwise known as sluing) or vertically (up and down). The tamper is a large on track machine and has to be hired for specific jobs. The process of tampering is a very slow process, about 1 metre per minute.

|

|||||||