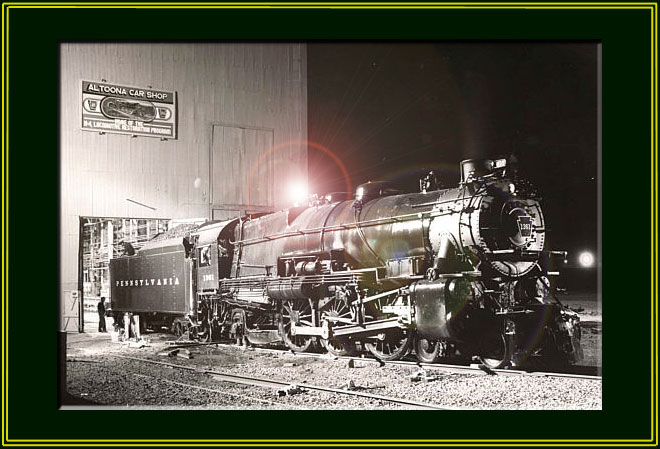

The PRR K-4s #1361

Steam Locomotive Restoration Project

Page 21

(This site is provided as a courtesy of the Altoona Railway Museum Club)

July 2005 K4 Update (continued)

These photographs were taken between January 2005 and July 2005 by Charles Cantrell, 1361 Volunteer.

|

41. Newly fabricated gibbs for the locomotive spring rigging. |

42. A gibb being machined. Note the block fabricated by the contractor to hold the gibb during the milling process. |

||

|

43. Work continues on the new tender tool compartment. |

44. The new tender tool compartment is place into position for fitting. |

||

|

45. Work continues on the new eccentric rod. |

46. One of the eccentric rods after it’s return from stress relieving. Stress relieving was necessary before work could continue. |

||

|

47. A finished spring hanger gibb shown next to an old one. |

48. A box of completed gibbs. |

||

|

49. The tender tool compartment shown with the steps, doors, and grab bars in place. |

50. The old tender tool compartment door undergoes dismantling for salvageable parts. |

||

|

51. A new tender tool compartment door being fabricated in the roller. |

52. Newly machined universal joints for the stoker augers for the stocker feed chute. |

||

|

53. More work on the eccentric rods. |

54. And more work on the eccentric rods. |

||

|

55. A front view of the tender showing both tender tool compartments installed. |

56. A close up view of the tender steps being fitted. |

||

|

57. Work begins on the tender hand brake assembly. |

58. A newly machined shaft for the hand brake assembly. |

||

|

59. Locomotive spring rigging parts are sent out for stress relieving. |

60. Bracket for tender coal bunker door hinges and tool compartment doors being installed on the tender. |

||

|

61. Work continues on the tender tool compartment and steps. |

62. The coal bunker floor is installed for a trial fit, |

||

|

63. A coal bunker door hanger is readied for installation. |

64. The eccentric rods are almost complete. |

||

|

65. Another view. |

66. Another view. |

||

|

67. The completed eccentric rods after installation of grease fittings. The completed rod s weigh 49 pounds a peace after machining. That’s 791 pounds less than they started out weighing. It took 400 hours to manufacture the rods. |

68. Another view |

||

|

69. Volunteer Chad Frederickson bevels the edges on the tender rear floor corner sections tender. |

70. The tender deck floor drain is cut into the deck plate as well as the drain pipe mounting holes. |

||

|

71. The tender lift eye is fitted into place. |

72. New shafts for the tender water delivery valves had to be fabricated. |

||

|

73. The tender coal bunker doors are trial fitted. |

74. New tender pullin bars (old time railroader slang for pull bars) have to be fabricated. |

||

|

75. The bar stock mounted in the Kearney and Trecker mill for milling. |

76. The nearly completed pullin bar. |

||

|

77. The bar is remounted in the mill for further work. |

78. Tender water delivery valves after buildup and machining. New gaskets have also been applied. |

||

|

79. Close up of the machining on the water valve. |

80. Machinist Joe Kadelak machining one of the pullin bars. Two are required and both had to be replaced due to wear. |

||

|

81. Volunteer Tom Diehl needled scaling a superheater prior to hydrostatic testing for leaks or other defects. |

82. Volunteers Walter Elvidge and Chad Frederickson assist contractor Bill Frederickson placing a superheater in the test fixture. |

||

|

83. Volunteers Walter Elvidge and Chad Frederickson hydrostatic testing a superheater. The pressure gauge reads 1200 psi. |

84. Volunteers Walter Elvidge, Chad Frederickson, and Charles Cantrell assisting contractor Bill Frederickson in banding the superheaters. Altoona employee Mike Tillger is removing cinder guards and old bands prior to rebanding. |

||

|

85. Another view of the banding process. |

|

|

All, Thanks for enduring the delay on website updates. Future updates will be posted intermittently. Regards. The Webmaster.

Stay tuned for additional photographs of the PRR K-4s #1361 Restoration!!