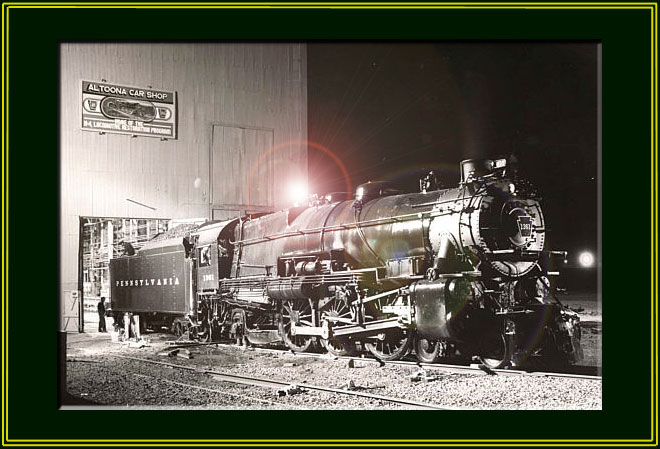

The PRR K-4s #1361

Steam Locomotive Restoration Project

Page 20

(This site is provided as a courtesy of the Altoona Railway Museum Club)

July 2005 K4 Update

These photographs were taken between January 2005 and July 2005 by Charles Cantrell, 1361 Volunteer.

|

1. New eccentric rods had to be made to replace the two that were missing. Pictured is one of two steel bars marked up prior to machining. The bar weighs 840 pounds. |

2. Another view of the marked up bar stock. |

||

|

3. The eccentric rod bar stock is clamped down in the Gray horizontal shaper in preparation for trimming down to size. |

4. Another view of the eccentric bar stock in the Gray shaper. |

||

|

5. The beginnings of a new thrust washer for the stocker. |

6. A locomotive spring equalizer clamped down in the Kearney and Trecker mill for machining after build up. |

||

|

7. Locomotive spring equalizers and hangers have just undergone build up in the weld shop. |

8. The throttle body is shipped out to the Strasburg Railroad Museum for overhaul. |

||

|

9. The stoker assembly is brought back in for fitting of a new thrust washer assembly. |

10. Tom Diehl and another volunteer drill holes in the tender deck in preparation for riveting. |

||

|

11. Volunteers Chad Frederickson and Charles Cantrell burn out the old rivets from around the cistern hatch to remove the hatch from the old deck for reuse later. |

12. The hatch after the deck was removed. |

||

|

13. Continued machining of the thrust washer for the stocker. |

14. A close up view of the machining process. |

||

|

15. Fabrication of new equalizer bushings begins. |

16. Finished brake rigging parts after buildup and machining. |

||

|

17. New ladder for the tender water hatch is fabricated. |

18. A view of the new ladder installed for trial fit. |

||

|

19. View of the new tender deck and water hatch. |

20. Another view of the tender deck. |

||

|

21. Machining begins on the new eccentric rods. |

22. Locomotive equalizers back in the mill for further millwork. |

||

|

23. An equalizers after new bushings have been fitted. |

24. Another view of the equalizers. Note the new bushings that have been installed. |

||

|

25. Volunteer Walter Elvidge machines new hatch pins for the tender water hatch doors. |

26. Close up of the old pin and the beginnings of a new one. The slot will have to be machined next. |

||

|

27. The eccentric rod is clamped down for further milling. |

28. The same rod after milling. |

||

|

29. A view of the equalizers after having the shoulders radiused by volunteer Charles Cantrell to prevent interference with the frame. |

30. A slot had to be cut into the equalizer with as die grinder to facilitate welding the bushings into place. |

||

|

31. Work continues inside the tender. |

32. A new bolt being fabricated for the locomotive brake cylinders. |

||

|

33. Another view the eccentric after further milling. |

34. The eccentric rod back in the mill for more work. |

||

|

35. The same rods after milling. |

36. An old tender tool compartment is brought back into the shop for dismantling of salvageable parts such as the grab rail and to act as a template. |

||

|

37. Inside view of the tender tool compartment showing the determination. |

38. Fabrication of new parts for the tender tool compartment. |

||

|

39. View of the tender floor seem and brace plates. The floor seem will be welded and the plates will be riveted into position. |

40. View of the newly fabricated slope sheet brace. |

All, Thanks for enduring the delay on website updates. Future updates will be posted intermittently. Regards. The Webmaster.

Stay tuned for additional photographs of the PRR K-4s #1361 Restoration!!