Steam Locomotive Improvements

on the FCAF

|

| Installation of Lempor exhaust system |

| Provision of streamlined main steam pipes |

| Improvements to oil burner |

| Heavy insulation of cylinders, boiler, and steam pipes |

| Thorough overhaul of mechanical components |

| Turning drivers to "high adhesion" profile developed by Porta |

| Ergonomic modifications to cab and controls |

Upon its return to service, Camila was

a complete success, with noticably improved

performance, both in terms of power and fuel and

water economy.

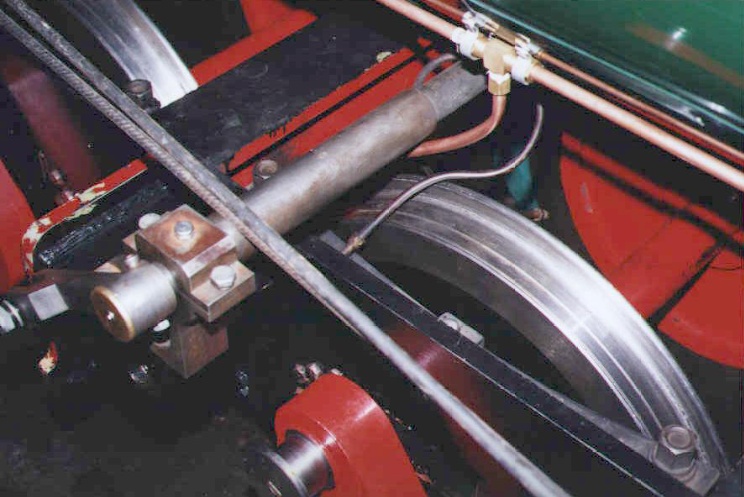

The photo below shows the highly

insulated cylinder and steam chest- "sealed for

life" as advocated by David Wardale. Wardale notes

in his book The Red Devil that steam

locomotive cylinder insulation was typically

maintained in deplorable condition. (For example, I

have yet to find a photo of a single engine

operating in Zimbabwe with insulated cylinder

heads!) The insulation applied to Camila's cylinders

appears to be an excellent start towards Wardale's

recommended permanent cylinder insulation.

View shows Camila's cylinder showing heavy insulation, and proportional feed lubricator drive with "between the rings" oil delivery to the valve heads. Also note direct, well-insulated steam delivery pipe to steam chest.

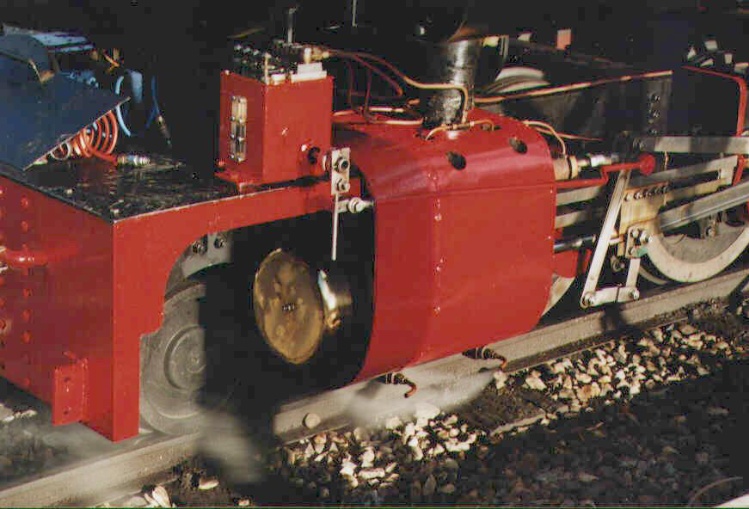

Camila's high adhesion wheel profiles

are clearly visible in this photo. Copper pipe runs

are for flange lubrication. (Note- the "high adhesion"

tire profile was developed by Porta and includes a

step and a groove in the running surface of the wheel,

the idea being to keep contaminants such as oil or

grease away from the part of the wheel in contact with

the rail.

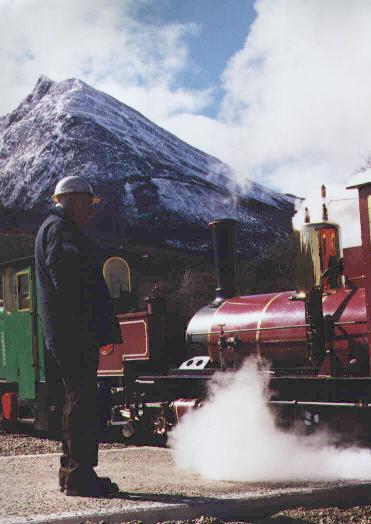

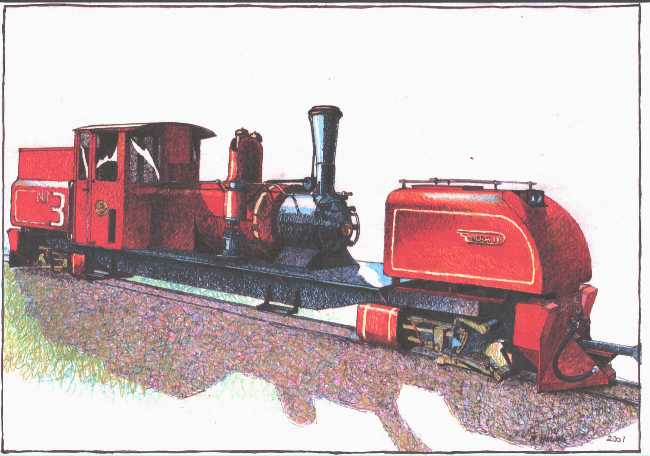

Camila with raised boiler next to Garratt

locomotive "Nora"

This photo shows Camila's boiler temporarily installed in a raised position. Shortly after Camila's return to service after the Stage I modifications, an unrelated boiler fault occurred. The boiler had to be removed and shipped to Buenos Aires for repairs. While the boiler was disconnected, the opportunity was taken to develop some data for Camila's Stage II modifications. This anticipates the probable mounting of the new or modified boiler to be fitted to Camila for Stage II of the modifications to the engine. The much higher mounting position will allow a much deeper firebox to be fitted, providing a great increase in firebox volume. The Lempor exhaust stack was temporarily installed and the engine was towed around the railway yards to check clearances which were just (!!) sufficient. The degree to which the boiler was raised (385 mm) can be judged from the distance between the Lempor exhaust nozzles (normally located within the smokebox) and the bottom of the smokebox.

This photo also gives a good idea of the

probably proportions of the Second Generation Steam

(SGS) locomotive (0-6-0T or 0-6-2T wheel arrangement)

that may be built in the future for the FCAF and for

production for other narrow gauge tourist railways.

This new engine is to be a 2-cylinder compound,

incorporating and optimizing all the existing and

planned improvements for Camila.

Taken March 2001, drivers were being

trucked to "nearby" Rio Grande (only 250 km from

Ushuaia) for replacement of a defective axle roller

bearing. The sign gives distances of 100 km to Punta

Maria, 134 km to Rio Grande, and 582 km to Rio

Gallegos, where the "neighboring" RFIRT terminates.

Smokebox after 41 days in steam. Note

very low mounting of the Lempor exhaust nozzle to

maximize available total height of stack. Also note

fully contoured radius of stack inlet, rather than

just a "bellmouth" inlet as was traditionally used,

which minimizes flow restriction of exhaust gasses

into the stack.

Side/rear view of Camila. Clearly visible are Lempor chimney (note significant taper compared to original stack), air pump exhaust external to chimney, high degree of insulation fitted to air pump steam delivery pipe, water tank gauge, and extra test instrumention fitted inside the cab. New diesel "Tierra del Feugo" built by Girdlestone Rail is visible in the background.

Camila's modifications show that

"tourist" locomotives need not be brutally simple

engines devoid of any modern design features. The

value of the modifications has been proved in

day-to-day service on a heavily trafficed,

geographically isolated railway where reliability and

economy are paramount.

prior to extensive overhaul in 2001

and renaming as "L. D. Porta"

photo ® by Martin Coumbs

"At the age of

77, Ing. L. D. Porta supervises steam leakage tests

on FCAF locomotive 'No. 2'- October 1999."

"L. D. Porta looks on as steam escapes from static steam leakage test to FCAF "No. 2". The result was 67% leakage!! Porta still holds the world record at 2% (only) with Rio Turbio Mitsubishi 2-10-2s! Note snow capped mountain in background. Porta has a particular affection for Patagonia and says his best years were spend in Rio Gallegos!"Photo: Shaun McMahon, October 1999

The design of a variety of improvements to the locomotive was conducted in 2000 and the locomotive was extensively rebuilt in 2001. For details of the extensive re-build of No. 2, follow this link: Rebuild of FCAF #2

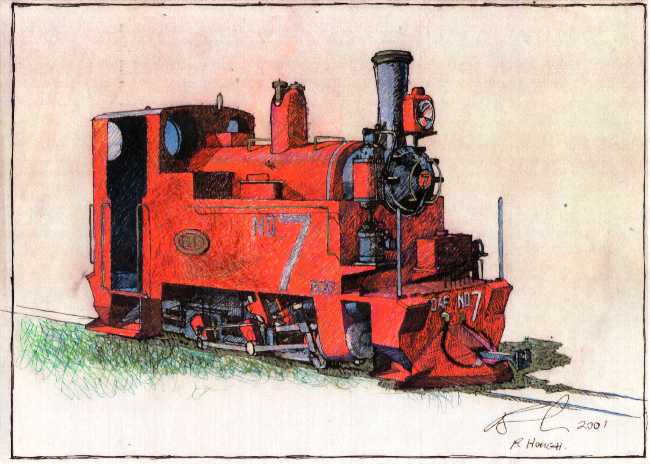

Following the experience gained by the

modernizations of locomotives No. 2 and Camila, the

FCAF elected to construct a new locomotive with these

and additional improvements. No. 5 was

constructed in South Africa by Phil Girdlestone and

associates and delivered to the FCAF in 2005.

Some parts fabricated in Argentina and originally

intended for a sister engine to No. 2 Nora (now L. D.

Porta) were used. However, the majority of the

locomotive is new construction. An all-new

boiler, designed to appropriate codes and

incorporating both a Belpaire firebox and superheating

was provided. This locomotive incorporates

lessons learned from the modernizations and operation

of other FCAF steam locomotives and is the line's most

powerful steam locomotive.

For more details on the engine, see Martyn Bane's page at: http://www.martynbane.co.uk/modernsteam/pg/fcaf5/fcaf5.html

Stage II improvements were planned for Camila, to

consist mainly of improvements to the steam circuit,

including high superheating, larger, improved piston

valves with larger steam chests, a re-designed Lempor

or new Lemprex exhaust system (to suit the superheated

steam circuit), a feedwater heater, and an enlarged

firebox and improved oil burning system. Depending on

the extent of modifications required, a new boiler may

be fabricated rather than modifying the existing one.

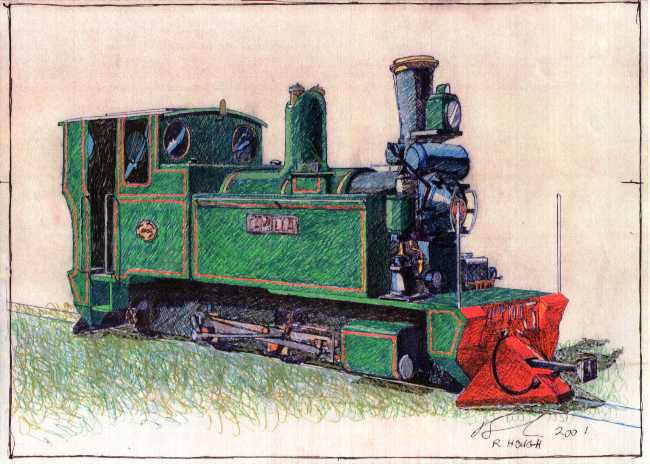

New steam was also planned for the FCAF

and other tourist railways in the form of the

locomotive shown above. Design work began in 1998 on

this locomotive, planned for use on the FCAF and other

small tourist railways. While several design details

have changed since the sketch above was prepared, the

image gives a good idea of what the locomotive will

look like. The locomotive will be a 2-cylinder

compound, with an 0-6-0T or 0-6-2T wheel arrangement.

The LVM 803 designation is in keeping with the other

modern steamers planned or designed under Ing. L. D.

Porta's guidance: the LVM 800 0-6-2T shunting

locomotive for Cuba; LVM 801 2-8-2T/tender passenger

locomotive for Tren a Las Nubes (Train to the Clouds),

Salta, Argentina; LVM 802 "standby" steamers for

Spain; and LVM 803, Tranex Turismo S.A.'s FCAF,

Ushuaia.

Since Ing. Porta's death in 2003 the

fate of these projects is uncertain. A third Garratt

has been planned for the FCAF, but the status of this

is currently not known.

|

For more information on the railway, visit the Official Homepage of the FCAF at: |

|

Return to The Ultimate Steam Page |