|

|

Steam Locomotion in

the 21st Century

The Recent History of

Steam Locomotive Development

|

The Rebuild of FCAF's Garratt

Locomotive No. 2

the "L. D. Porta"

updated February 23, 2004

photos, info and most text

courtesy Shaun McMahon except as noted

|

As

readers will appreciate, being a Garratt

locomotive (as opposed to a conventional

locomotive) the complexity of the work

in hand is far greater than it was for

Camila, the FCAF's other steamer which

was modernized in 1999. Dismantling and

full inspection of the loco began on

26th February, 2001 (see photos below)

and the rebuild was completed in late

2001. Photos of the work follow at the

bottom of the page. A brief summary of

items attended to during the overhaul

and modifications is as follows:

-Improved,

streamlined live and exhaust steam

circuits coupled with a high degree of

insulation for the steam pipes

-Fitting of Lempor exhaust system,

Kordina and DeLaval blower

-Improvements to combustion system

-Improved and extended mechanical

lubrication inclusive of proportional feed

-Modified driving axle suspension

-Improved boiler insulation

-Improved cylinder insulation

-Improved cab layout to aid single manning

conditions

-Raising of cab so as to allow the driver

to stand up properly

-Raising of boiler 300 mm to allow better

primary air flow to firepan, allow the

later addition of a primary air heater,

and to provide more room for the fitting

of improved steam circuits

-Increased feedwater capacity

-Increased fuel capacity

-Flange lubrication

-Motion ovberhaul

-Valve gear overhaul

-Piston and valve ring replacement

-Wheelset replacement and provision of

high adhesion wheel profile

-Evaluation of work to be carried out at

stage 2 full rebuild

-Improved sealing of smokebox door

-Replacement of blowdown valve

-Attending to security aspects of existing

boiler

-Modification of existing brake gear

-Provision of handrails so as to aid

safety aspect of climbing up on locomotive

-Fitting of test gear so as to evaluate

performance of locomotive in traffic

-Replacement of existing reversing

screw (deferred until later in

2002)

|

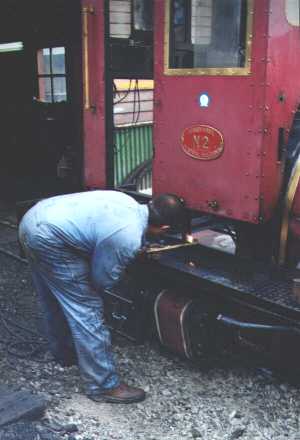

Overhaul/modification of No. 2-

February 2001

|

No. 2, with water and fuel

tanks removed, stands outside the FCAF

workshop awaiting dismantling. |

| No. 2's auxiliary water tanks,

front water tank, and rear combined

water/fuel tank are visible in front of FCAF

No. 3 Camila. |

|

|

|

No. 2's cab being removed via

a little "gentle persuasion". Reverser

mounting bracket had to be cut to allow the

cab to be removed. |

|

Removing No. 2's cab; water

and fuel tanks seen on the right. |

| With first stage dismantling

complete, No. 2 is pulled clear of the

works. No. 2's regular driver (in high

summer season), Chris Parrott, is just

visible driving diesel Tierra del Fuego. |

|

|

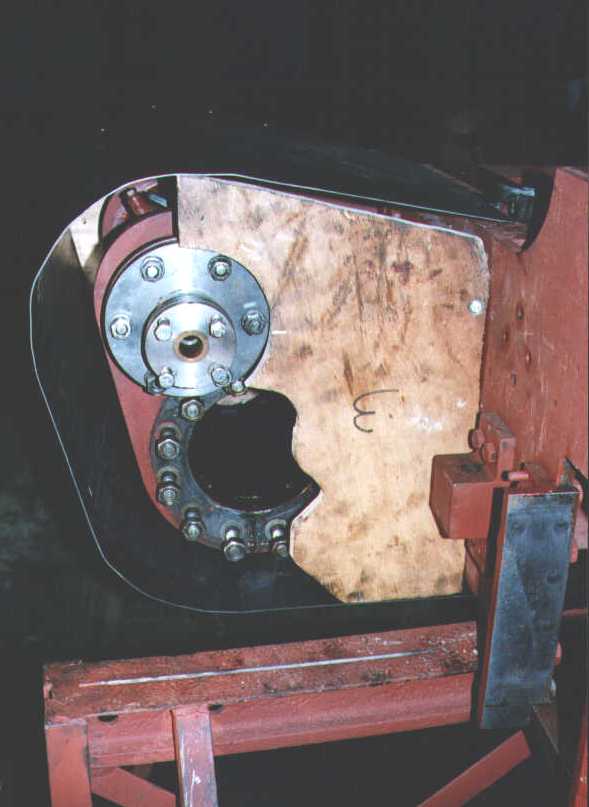

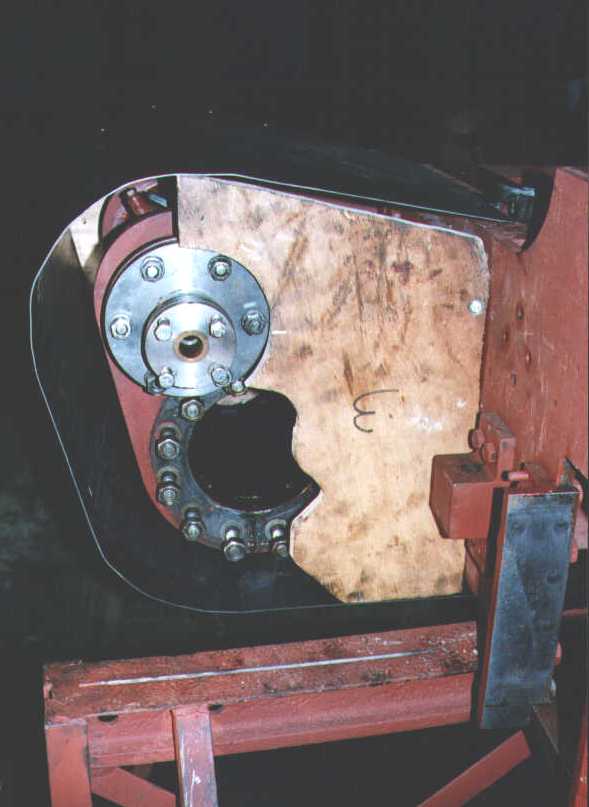

No. 2's smokebox showing

original blastpipe, which was replaced by a

Lempor Ejector during the rebuild. Compare

this to the photo below showing the new

Lempor exhaust system fabricated by

Girdlestone Rail. |

| Camila shunts No. 2's boiler,

mainframe, and power units in the works yard

at Estacion Fin Del Mundo. |

|

|

|

No. 2's freshly primered

original boiler (no. 1) on the mainframe

inside the shop at Ushuaia. The spare boiler

(no. 2) was modified by Girdlestone Rail in

South Africa (see below) and was used to

replace this boiler during the overhaul. |

| No. 2's front power unit

stripped for overhaul and modification

inside the workshop at Ushuaia. |

|

|

RFIRT No. 109

One of Porta's famous Mitsubishi-built

2-10-2's now lying derelict. Visible in

this photo are the throttle handle and

manual screw reverser which was to be

fitted to No. 2 during its overhaul. This

had to be delayed until later this year so

that the engine could be placed back in

service on schedule.

|

| No. 2's water tanks undergoing

modification at Ushuaia. Tanks were

significantly enlarged and re-countoured. |

|

|

Modified Boiler No. 2 for

No. 2

in Girdlestone Rail's Shop in South Africa

|

|

Modified Driving

Wheelsets for No. 2

Featuring Porta "High Adhesion" Profile

at Girdlestone Rail in South Africa

|

|

New Lempor Exhaust System

for No. 2

|

|

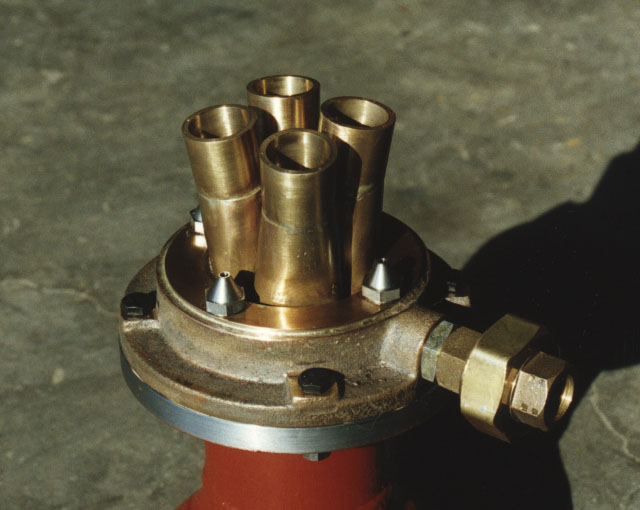

Lempor Exhaust Nozzles

and Blower for No. 2

|

|

New Oil Burner for No. 2

Oil is atomized and

ejected by steam around the perimeter of

the gap at the top of the assembly

No. 2 Rebuild Progress on the FCAF

Shaun McMahon reports from Ushuaia that

good progress is being made on Garratt

locomotive No. 2's overhaul and

modernization. (photos courtesy of Shaun

McMahon)

FCAF No. 3 Runs Around Its

Train at Estacion Fin Del Mundo. In the

background is the boiler and mainframe of

No. 2 No. 2 mounted aboard one of the

railway's flat bogie wagons. August 25,

2001.

No. 2's front power unit

mounted on supports for easy access during

rebuild

Photo of the power unit

showing the cylinders prior to

installation of jacketing

No. 2's front power unit

mounted on supports, showing fabrication

of cylinder jacket to allow extra-heavy

insulation of all cylinder external

surfaces in accordance with Porta's latest

recommendations.

No. 2's front power unit,

mounted on supports showing

nearly-complete cylinder jacket on one

cylinder

|

No. 2's "new"

boiler shown in its new position

(raised considerably compared to

the original installation) with

new Lempor exhaust system

installed. |

| A closeup of No.

2's smokebox showing the details

of the Lempor exhaust stack and

steam exhaust piping below. |

|

|

Another view of

No. 2's main frames with the

boiler installed, showing

greatly increased cab height

which allows "full scale" driver

to work in comfort! Greatly

increased height of Lempor

exhaust stack is evident. |

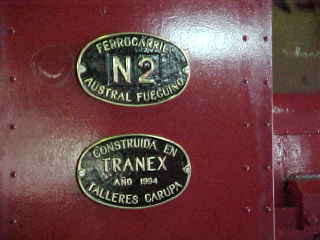

| No. 2's handsome

brass builder's plates on the

cab side. |

|

|

Backhead view of

No. 2's new boiler with some cab

accessories installed. |

| Back of No. 2's

cab showing greatly increased

height for improved operator

comfort. |

|

|

Bottom view of No.

2's firebox, showing new oil

burner and "flared" air

admission inlets to promote

turbulence for better fuel/air

mixing and improved combustion

efficiency. |

| One of No. 2's two

engine units showing partially

insulated cylinders. Note

"pocket" on front surface of

cylinder to allow installation

of extra heavy insulation. |

|

|

No. 2's new rear

water tank. Height and profile

have been signicantly altered to

provide greatly increased water

capacity while maintaining good

visibility. Center opening

(painted black) is for

installation of new fuel oil

tank (shown below). |

| New fuel oil tank

ready for installation in recess

provided in rear water tank. |

|

|

Side view of new

rear water tank. |

| Rear view of new

high capacity front water tank. |

|

|

Side view of new

front water tank showing

"streamlined" profile, similar

to No. 2's "big sisters" such as

the South African Railways GMAM

Garratts. |

|

No. 2's rebuild was completed in

December 2001, and the locomotive was renamed "L. D.

Porta" before testing and tuning up was begun. Tuning

up was completed in early 2002 and the locomotive was

returned to regular service.

|