|

Steam Locomotion in the 21st Century The Recent History of Steam Locomotive Development |

Updated 4 February 2022

| One of the most

important components of virtually all steam locomotives is

the exhaust system. Early steam locomotive builders such

as George Stephenson discovered the principal upon which

virtually all steam locomotives built since have used. By

happy accident, they found that directing the "waste"

steam exhausted from the cylinders at the end of each

stroke up the boiler's chimney greatly increased the air

flow through the fire. This caused the fire to burn hotter

and faster, allowing a locomotive boiler to generate

dramatically more steam than stationary boilers of similar

size.

As locomotive design progressed, builders realized that the proportions and configurations of the chimney and the exhaust pipe had a significant effect on how well the exhaust system worked. A major concern was the effect of backpressure on the performance of the locomotive's cylinders. Backpressure was a measure of the restriction of the exhaust steam flow from the cylinders at the end of each stroke. The locomotive exhaust could be built with a small exhaust nozzle, which caused the exhaust steam to jet up the stack at high velocity, which would produce excellent gas flow through the boiler (draft). However, this small nozzle would impede the flow of the exhaust steam from the cylinders, causing excessive backpressure. This backpressure saps power from the locomotive's cylinders, reducing the locomotive's performance. Good draft increased the locomotive's steaming rate making more steam available to generate power, but high backpressure could cancel this out. This was the chief task of locomotive exhaust designers: how to produce the maximum draft while producing the minimum back-pressure on the cylinders. Until well into the 20th century, the physics of gas

flow were not understood and the theories and laws which

could be used to design exhaust systems did not exist.

Consequently, for much of their existence, locomotive

exhaust systems were developed through a process of

trial-and-error. Chapelon, Porta, and others strove to

apply principals of engineering and physics to exhaust

system design. |

|

|

This exhaust system, from a locomotive in New Zealand, is similar to that of many 19th Century locomotive exhaust systems. The steam nozzle is at the bottom, and it exhausts through a "petticoat" and finally up through the main chimney (the separate petticoat was a 20th century development). This chimney includes a spark arresting apparatus, which forces the exhaust gases through several turns in order to make sparks and cinders drop out into the bottom of the spark arrestor. |

|

This drawing shows a typical locomotive

exhaust system from a U.S. steam locomotive built in the

20th century. The drawing shows a cross-section of the

smoke box at the front of a locomotive boiler (the boiler

would be to the left of the view). The steam nozzle is at

the bottom of the smoke box, exhausting its steam jet up

the stack which is at the top. The drawing also

illustrates the empirical design formulas which were used

to size the components. After building hundreds of exhaust

systems, designers decided that the proportions of the

components listed above would work best for most

locomotives under most conditions. |

|

This drawing shows an early Kylchap exhaust. Chapelon used the exhaust splitter developed by Finish engineer Kylala, which divides the exhaust stream into four parts. The Kylchap draws in gases from more than one level of the smokebox, which Chapelon believed to be an important feature in providing an even gas flow through the many tubes of the boiler. Later Kylchap exhausts used two levels of entrainment and two or even three stacks. |

|

The Kylala exhaust splitter was an important part of the Kylchap exhaust system. |

|

In the U.S., several railways developed improved exhaust systems using annular exhaust nozzles and larger stacks. |

|

Plan view of the so-called "waffle iron"

exhaust nozzle used in the exhaust system shown above. |

|

The Lemaitre Exhaust was developed by

Lemaitre, a mechanical engineer from the NORD Belge in

France. The Lemaitre featured 5 nozzles in a circular

pattern exhausting up a large diameter stack, with a

variable area nozzle exhausting up the center. British engineer Bullied used a simplified version of this on the locomotives he built, omitting the variable area center nozzle. |

|

|

In the late 1940's, Dr. Adolph

Giesl-Gieslingen developed a new exhaust design called the

Giesl Ejector. He patented this device and it was applied

to thousands of steam locomotives all over the world. The

Giesl Ejector featured a series of small in-line nozzles

exhausting up a thin, oblong chimney. This system was patented and produced under license, and was applied to many steam locomotives around the world in the 1950's, and 1960's, giving improved performance and fuel economy. Unlicensed copies of these exhausts were also produced and applied to some locomotives in China. drawing courtesy Stuart Kean |

|

This diagram shows the Lempor (Lemaitre-Porta) exhaust developed by Porta and applied to many locomotives. Porta also developed an extensive theory describing the performance and design of these exhaust systems. |

|

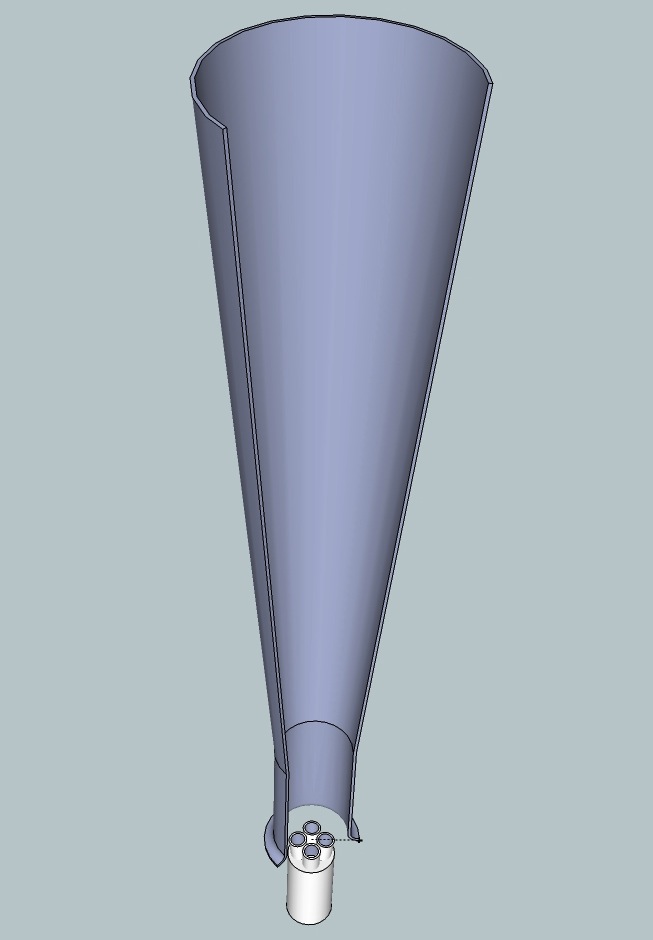

Here is a 3-D rendering of a Lempor

ejector. The picture shows the full exhaust system with a section taken out of the stack to show the inside. The system shown uses the revised design developed by Porta with a non-tapered mixing chamber (the lower portion of the stack) and a 10 degree angle between the nozzles, as experimentally determined to be optimum by Wardale. |

|

One of the most recent new exhaust systems was developed for the Garratt locomotives of the Rhodesian Railways. These were known as "pepperpot" exhausts and were later fitted to many Garratts which were overhauled and restored to service in the early 1980's in the new country of Zimbabwe. This nozzle arrangement was used in combination with a larger chimney, and was developed as alternative to Giesl exhausts experimentally fitted to Garratts in the 1960's. The pepperpot exhaust was preferred because (1) it was locally developed (the Giesl was proprietary and royalties had to be paid for its use) and (2) the Pepperpot was less susceptible to unauthorized tampering which tended to cause problems with the Giesls in normal service. |

|

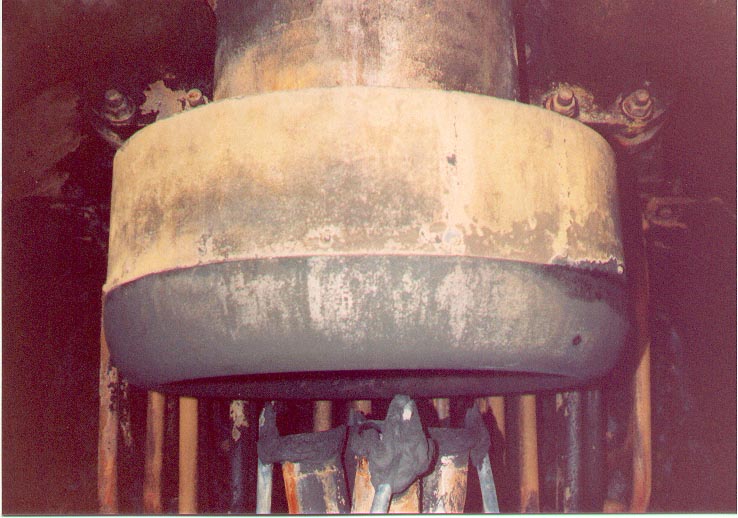

For the last years of his life, Porta

worked on the development of a Lemprex exhaust

system, a further advancement on the Lempor. The Lemprex

incorporates features to maximize its performance within

the limited height available on a steam locomotive. This

photo shows one of the last exhaust systems installed

under Porta's supervision, on the Donna Teresa Christina

Railway in Brazil. This exhaust incorporates at least some

features intended for the Lemprex, namely the skewed

exhaust and blower nozzles which were to give a swirling

motion to the exhaust gases as they passed out of the

stack for improved mixing and performance. |

|

Some of the most recent exhaust

development work was carried out by Dr. Jos Koopmans of

the Netherlands, who wrote his doctoral thesis on exhaust

systems some years ago, later published as the book "The

Fire Burns Much Better". In early 2018, Waterloo Central Railway 0-6-0 No. 9, formerly Essex Terminal No. 9, was fitted with a multiple jet exhaust system designed by Dr. Jos Koopmans and fabricated by steam enthusiast Michael Guy. This system made use of the existing, relatively short chimney, and omitted the two separate petticoats provided in the original exhaust system. A new extension raises the nozzle assembly so that the nozzles are correctly aligned with the existing stack. Performance with this system has been significantly increased over the original exhaust. In 2016, Dr. Koopmans installed a similar system in the UK on King Edward II 4-6-0 No. 6023. This system successfully restored the locomotive's performance after the stack (chimney) height had to be reduced by 4 inches to meet new clearance requirements. Photo courtesy of Michael Guy. |

Back to Top |

Return to the Exhaust Systems Page |