|

|

Preface

A word about the current P:64

standards. The original proposal which was 3/16" AAR proved unworkable

for US prototypes in small scales.

Enter The NMRA Proto Effort. This effort started with 1/4"AAR and worked till that became P:48. The current Standards use an engineering allowance called FIT with any scale less than 1:56. As demonstrated by our original proposal we do not believe this necessary above 00 scale (1:72). Therefore; We had asked that the spread sheet be modified to reflect this, the result proved not worth the effort

The previous NASG

Recommended Practices on this site are not current and are not truly Proto as they contain

compromises to accommodate RP25 wheels. That said they are achievable

with commercial components and using Code 88 wheels from either Des

Plains Hobbies or NWSL a semi-proto layout can be modeled. The documents on the NASG site are not in agreement with anyone else.

Scale

Track & Wheel Relationships

To ensure Interchange and reliable performance STANDARDS are designed

so that Track and Wheels constructed within prescribed limits will meet

the following related conditions closely parallel to prototype

practices.

1. TRACK GAGE (G in S-3) is the distance between railheads of two Stock

(running) Rails of a length of Track.

a. Straight (tangent) track should be laid as close to the minimum

limit of Track Gage as practicable.

b. Curved track may increase Track Gage as curve sharpness increases,

with such increase applied with care lest the wheel is inadequately

supported by the railhead, and side sway of equipment is exaggerated.

c. Three-point track gages should be constructed so as to fulfill these

requirements.

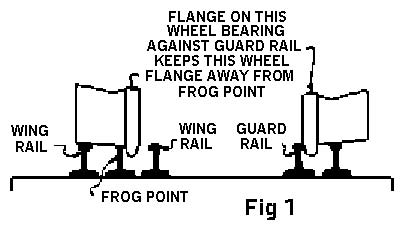

2. TRACK CHECK GAGE (C in S-3) is the distance from the flange side of

a Guard Rail to the flange side of the Frog it guards. WHEEL CHECK CAGE

(K in S-4) is the distance from the Back of the flange of one wheel to

the tread-side of the flange of the other wheel of a wheelset.

a. Maximum Wheel Check Gage should not exceed the minimum Track Check

Gage so that Guard rails will protect the Frog. See Fig. 1.

3. SPAN (S in S-3) is the distance between flange

sides of the Guard and Wing Rails at the guarded Frog.

BACK-to-BACK (B in S-4) is the distance between the Backs of the wheel

flanges in a wheelset at railhead height.

a. Maximum Span should be less than the minimum Back-to-Back distance.

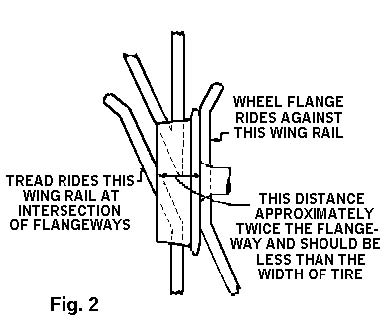

4. FLANGEWAY WIDTH (F in S-3) is the distance between flange sides of

the Wing and Frog Rails. TIRE WIDTH (N in S-4) is the distance between

the Back of the wheel flange at railhead height and the outer edge of

the wheel tread.

a. Maximum Flangeway Width at the point of the Frog should be less than

half the minimum Tire Width to ensure the wheel tread riding the Wing

Rail across the intersection of the flangeways until it is supported by

the Frog Point Rail. See Fig. 2.

b. Guard Rail Flangeway Width is limited at its maximum only by Track

Gage and Check Cage (G and C).

5. FLANGE CLEARANCE (H in S-3) is the vertical distance from the

railhead to the highest obstruction below it. FLANGE DEPTH (D in S-4)

is the vertical distance from the root of the flange to its outer edge.

a. Minimum Flange Clearance should not be less than the maximum Flange

Depth.

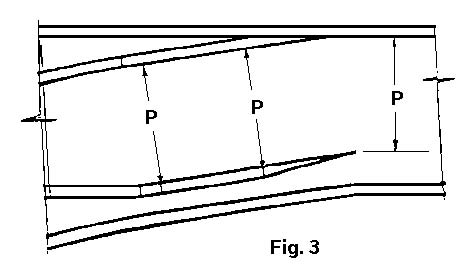

6. SWITCH POINT SPREAD (P in S-3) is the distance from the Gage Line of

the closed Point Rail to the outside of the open Point Rail. See Fig 3.

a. Maximum Spread (mechanical) should not exceed the sum of minimum

Back-to-Back plus minimum Flange Width (Bmin + Tmin) to prevent

interference.

b. Maximum Spread (electrical) should not exceed the dimension of 6.a.

above minus 0.005" to prevent short circuit between Point and Stock

Rails of opposite polarity where this condition exists.

|

write the Proto:64 Webmaster at tc2 AT dapenguin DOT net |