|

© 2001-2004 C&StL |

Les aiguillagesIl existe 6 type d'aiguillage de base. Ces types d'aiguillage peuvent être contrôlés soit de façon manuelle, soit de façon electrique, soit par les deux facons. Dans ce dernier cas, on dit que les aiguillages sont "à double commande". Nomenclature

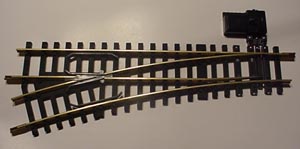

Voici les différentes parties de l'aiguillage: Aiguilles: Ce sont les pièces mobiles de l'aiguillage, qui pemettent de sélectionner la route à prendre. Pointes: Les pointes sont le prolongement des aiguilles. Elles se terminent au coeur du croisement. Coeur du croisement: C'est la pièce qui permet aux roues du train de franchir les rails transversales. Contre-rail: Les contre-rails aident à garder les roues du trains alignées pour la route à suivre, en cas où une roue franchirait mal le coeur de croisement. Si une roue touche au contre-rail, c'est qu'il y a un problème d'enlignement. Talons: Les talons sont les rails qui partent du coeur du croisement pour donner naissance à la nouvelle route. Tringle d'accouplement: C'est ce qui retient les aiguilles ensemble. Cette pièce est mue par l'appareil de manoeuvre. Appareil de manoeuvre: C'est là qu'on actionne l'aiguillage, à l'aide d'un levier. Si l'appareil est à commande manuelle, il y a aussi une cible qui indique la position des aiguilles à l'équipe du train qui approche. L'appareil de manoeuvre peut aussi être électrique et être contrôlée à distance (parfois plusieurs milliers de kilomètre!). Si l'appareil de manoeuvre est électrique mais qu'il dispose aussi d'un mécanisme accessible sur place, on dit qu'il est "à double commande". Les types d'aiguillage |

| Click here to see an enlargment of the picture, with the name of all component. |  |

Here are the different components of a switch:

Switch points: Those are the mobile rails of switch. They will align the wheels to one or another route.

Toes: The toes are the rails extending from the switch points to the frog.

Frog: The frog is the part that allows the wheels to cross over the adjacent rail.

Guard-rail: The guard-rail helps to keep the wheel correctly align in the switch. It prevent the opposite wheel from jumping the track in the frog. Under normal condition, a wheel is never supposed to touch the guard-rail.

Heels: The heels are the tracks extending from the frog to form the new route.

Throw bar: The throw bar hold the switch point together. It's the mouving part that allows to choose the route.

Switch stand: It's the part mouved by the railroad crews. A lever is attached to the throw bar. If the switch is manually actioned, a target indicated the selection of the route to the oncoming train crew. The throw bar can also be electrically actioned by a motor. This motor is controlled from a distant point, sometime thousands of kilometers away! If the motor can manually mouved on location by the train crew, the swich is called a double command switch.

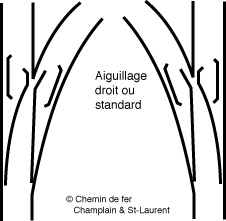

The main track stay straight all the way throught

the switch. The point allow the train to deviate to the left or the right.

The lenght of the switch depends on the topography of the terrain. As a

rule of thumb (on real train and miniature), we always must used the broadest

switch as possible.

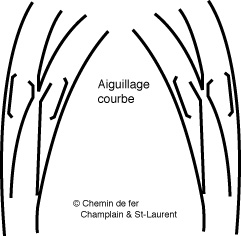

This type is a little bit different from the first

one, because the main track is not tangent (straight). The main track is

also curve. To be called a curved switch, the main track must cruve in the

same direction as the spur. Railroads never used a curved switch with a

main track curved in the opposite direction. The resulting "S"

will be a source of deraillement. Don't mix up this type and the "wye".

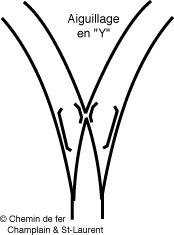

The third type of switch is the wye. It allows

a train to go either left or right, but not straight ahead. This type of

switch is not made in every scale in miniature. We can see it specially

on wye spur.

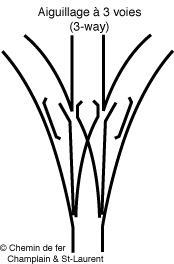

The fourth type is the 3-way switch. This switch

is complicated, because it contain two sets of switch point and two switch

stands. A train can go left, straight ahead or right. This type is very

rare, in real and in miniature. Railroads and hobbyists wants to minimize

the cost of installation and maintenance. It's cheaper to use two standard

switchs back to back. In case of a broken piece, it's easier and cheaper

to replace a regular switch then a 3-way switch. Most of the time, if you

want to use a 3-way switch, you have to do it yourself.

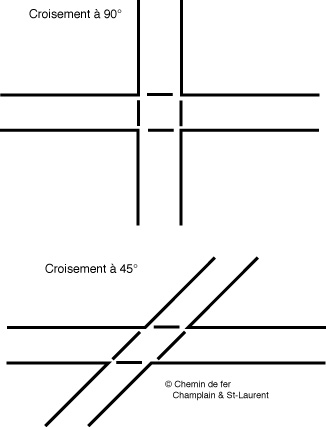

The crossing is not a switch. It consist of sets of frog assemble in a way to allows a track to cross another at ground level. The angle vary depending of the terrain and the tracks. Most of the time, crossing are used when the tracks of two competitors must cross each other.

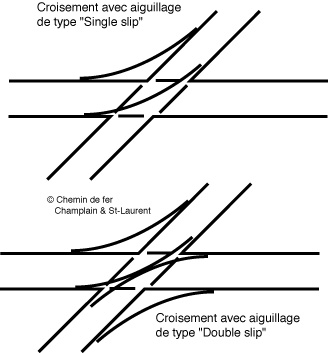

The single slip switch are a combination of a crossing and a standard switch. They allows a train to pass straight throught or to go on the other line. Normally use when two main line of the same compagny cross each other.

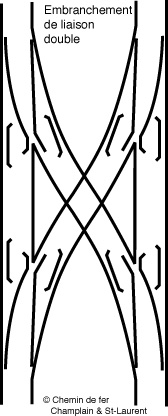

The double slip switch is the same as the single

slip type, except that it allows to cross in any direction.

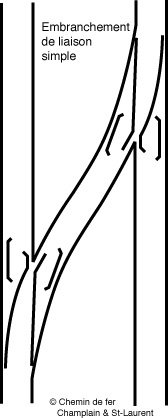

When two main lines are running close to each other, a crossover allows a train to cross from a track to the other one.

The double crossover allows a train to cross on the adjacent track, no matter of the direction of travel. For the same reasons as the 3-way switch (maintenance cost), this type are not common. Railroads prefer to use two single crossovers facing in opposite direction. Many advantages: No crossing (less set of frogs) and the junction will be made entirely of standard switchs.

The crossovers are part of what is called "controled

point", or interlocking. The switch are all coupled together. It is

impossible to throw a switch whitout throwing the corresponding switch on

the other track. If a switch is set to route a train on the other track,

the other switch will also be.

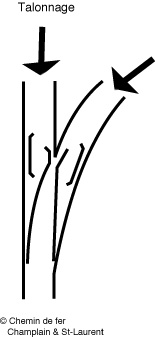

When a train arrive in a switch not facing the point, a problem can occur if the switch is not set correctly. Some switch are equipped with spring on the throw bar. This way, if the switch are not set for the route, the wheels will push and force the point to go on the good position. After the wheels are passed, the switch will come back in their previous position.

In the world of miniature train, if a switch not set correctly, a deraillement will occur (except for G scale, where switch got spring), because the wheels are not strong enough to push on the switch points. But on prototype trains, the cars and locos are so heavy that the wheels will push very hard on the switch points. Most of the time, the throw bar will pry and the switch points will move. A deraillement may not automaticaly occur.