In the early days of extracting trees from New Zealand's bush, the motive power to haul the logs to the sawmill

was predominantly the bullock, with a few horses used in small operations. The bullock was a pretty useful

animal it was strong and pulled well, particularly when coupled in a team, and at the end of a days work, it

could be turned out into the bush where it could feed and fend for itself until rounded up the next morning.

Horses were not so adept as this and had to be looked after, corralled and fed.

Initially the bullocks simply pulled the logs over the ground, which after a bit of use defined a purposeful

track through the bush. The weight of the log caused a groove to be formed in the ground and with a bit of rain,

this track could become very slippery, which was not always an advantage, particularly when it just churned up

into mud. So small diameter timbers were laid across the track and this formed a 'corduroy' road on which the

logs could be pulled without using too much energy.

With many of the bush

operations, the size and weight of the logs caused problems when hauled by bullocks, often

the log would take over on a downhill stretch and catch up on the poor animals. The large logs required bigger

bullock teams with their resultant problems so another method had to be found.

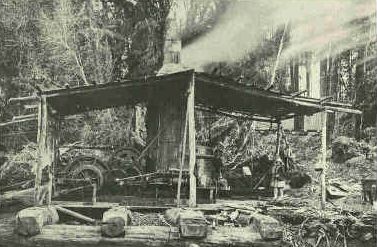

As the sawmills were steam

powered, it was a relatively easy matter to arrange a steam driven winch to haul the logs out of the bush, still

using the muddy grooves or the corduroy roads. On long hauls there had to be several winches placed at strategic

points and the hauling wire changed over once the log had been hauled up to a winch and required to be passed

on to the next winch.

With many of the bush

operations, the size and weight of the logs caused problems when hauled by bullocks, often

the log would take over on a downhill stretch and catch up on the poor animals. The large logs required bigger

bullock teams with their resultant problems so another method had to be found.

As the sawmills were steam

powered, it was a relatively easy matter to arrange a steam driven winch to haul the logs out of the bush, still

using the muddy grooves or the corduroy roads. On long hauls there had to be several winches placed at strategic

points and the hauling wire changed over once the log had been hauled up to a winch and required to be passed

on to the next winch.

The corduroy roads formed

the basis of a railway, the cross timbers offering to be sleepers and all that was needed

was a pair of rails. With materials right on the site, it was a simple matter to saw timbers to a roughly square

section and nail these to the cross sleepers at a gauge width apart. Wooden rails were often milled 125 x 75 mm

timber with a 75 x 50 mm cap laid on its side on top. This cap could be replaced when worn without disturbing

the basic structure.

The corduroy roads formed

the basis of a railway, the cross timbers offering to be sleepers and all that was needed

was a pair of rails. With materials right on the site, it was a simple matter to saw timbers to a roughly square

section and nail these to the cross sleepers at a gauge width apart. Wooden rails were often milled 125 x 75 mm

timber with a 75 x 50 mm cap laid on its side on top. This cap could be replaced when worn without disturbing

the basic structure.

Wheeled trucks were placed under the logs and the steam hauler used to move them along the track towards the sawmill.

It was still a laborious way of doing things and once again, there had to be a better way so the bushmen turned to

the steam locomotive.

Some of the earliest tracks had gauges of 838mm, 914mm, 1219mm and 1435mm, but like the Government railways, soon

established a standard track gauge of 1067 mm as, after all, that was about the only gauge in which locomotives

were available.

Actually, these bush tracks were not allowed to be railways and became tramways. Why a tramway and not a railway?

Where empowering legislation was required to obtain land, this was provided by the Tramways Act. The legal

requirements for a tramway are less than for a railway. Tramways face less strict regulations concerning the

fencing of the right of way, for instance, although certain limitations were often placed on a tramway operation,

such as the prohibition of running trains at night.

So what kind of steam locomotive was to be used? Early engines illustrated man's ingenuity, one being a converted

traction engine, but small used locomotives were becoming available from our national railway. These were light

four-wheel engines and with their short wheelbase and lightweight seemed to be ideal for a bush railway.

In the beginning of the bush tramway era, only rod engines were available. A rod engine is one on which the drive

from the cylinders is transmitted to the wheels by a connecting rod and the driving wheels are coupled together

with coupling rods. Hence the name. Sometimes called a 'direct drive' locomotive.

Early rod engines were all of fixed wheel-base, the articulated locomotive had not yet been invented, so to be

able to negotiate the rough track, and particularly very sharp curves through the standing timber, a short coupled

wheelbase was the answer and a majority of the early bush locomotives were of 0-4-0 wheel arrangement.

Stiff grades were another factor of timber railways and in order that the locomotives could haul an economic load

out of the forest, locomotives had to become heavier so that traction could be maintained.

The rigidity of the rod engines and their ever-increasing weight meant that the track had to be fairly graded and

laid down, not too steep and not too sharp on the curves. This however did not suit the lumbermen whose prime

purpose was to get into the forest, cut the timber and then move on to the next stand of millable trees.

Thus they tended to simply place the tracks on the existing ground with little regard for contour, grades or

foundations, because it was all going to be ripped up shortly and moved on.

So neither the early tracks nor the early locomotives were compatible and another way had to be found.

It turned out that these second-hand engines were perhaps not as useful as they might be, they were a little bit

harsh in their riding and tended to damage the wooden track, particularly as their wheels had usually been built

for narrow steel rails and were not suitable for wide timber ones. Also the light weight of the engine, while

acceptable on lightweight track, did not have the adhesion for the required pulling power. This was particularly

evident on the bush tramways because the track was not of terribly high construction standard, had very sharp

curves and tended to go up and down a lot as it followed the ground contours. The gradient of the lines,

expected by the woodsmen, were far too steep for these small light engines. Never the less, the small engines

did a wonderful job considering they had never been designed for such a duty.

Wooden rails were substituted

for steel ones often weighing no more than 10 to 15 kilograms per metre (20 - 30 lbs/yard). Tracks

were built with a minimum of earthworks on grades up to 1 in 10. Trestle bridges were common as the materials

were immediately to hand as were the skills to erect them, whereas earthworks meant heavy work and heavy carting.

Wooden rails were substituted

for steel ones often weighing no more than 10 to 15 kilograms per metre (20 - 30 lbs/yard). Tracks

were built with a minimum of earthworks on grades up to 1 in 10. Trestle bridges were common as the materials

were immediately to hand as were the skills to erect them, whereas earthworks meant heavy work and heavy carting.

So the bush tramway operators looked again at the problem and mainly took on a lesson learned by their overseas

counterparts and introduced the geared logging locomotive.

What were the advantages of geared engines over rod engines? Certainly, it could be said that they were a bit

more complicated and complex mechanisms are not exactly required in a bush-logging environment. The main

advantages of geared over rod engines is their flexibility in having at least two bogies to distribute the engine

weight over a large area and their gearing assists in maintaining power at low speeds.

A rod engine, with the usual two cylinders, gives four power strokes per driving wheel revolution with the

characteristic 'puff-puff' of exhausting steam. A geared engine, on the other hand, would often be geared between

the engine and driving wheels in a ratio of 1 to 2 and up to 1 to 7 depending on the gearing. So, a two cylinder

double acting steam engine on a geared locomotive would give eight to twenty-eight power strokes per revolution

of the driving wheels. In addition to this, the driving wheels of the geared engine were invariably smaller

in diameter than those of the rod engine and this would add to the ability of the geared engine to haul heavy

loads while surmounting severe grades and tight curves. In action they would sound like an express locomotive

at high speed, yet seldom exceeded about 15 km/h.

The other main advantage of the geared bush locomotives was their wheel arrangement. A locomotive running on

two small four-wheel swivelling bogies would be able to take sharper curves than a locomotive with four wheels

mounted rigidly within its frame. Logging engines could have two, three or four sets of four-wheel bogies and

all wheels would be driven. There were a few geared engines built very much like a rod engine, that is, having

a four-coupled wheel arrangement in a rigid frame. The difference from a standard rod engine was that the

cylinders drove a countershaft, which in turn was connected, to the wheels via reduction gearing. One or two

of these simply drove a jackshaft mounted between the main driving wheels and connected with those wheels by

the usual coupling rods.

Bush locos generally ran with their front end pointed up hill. This ensured that the firebox crown sheet was

always covered with water. If this were not so, then the heat from the firebox could distort the crown sheet

perhaps leading to catastrophic failure.

Train braking systems were usually

manually operated brakes on the log buggies supplemented by steam

powered brakes acting on the locomotive driving wheels. The log buggy brakes would be applied using a screw

mechanism that pressed a wooden block on to the wheel face to provide retardation. Early log buggies simply

had a wooden wedge to lodge between frame and wheel to act as a brake.

Train braking systems were usually

manually operated brakes on the log buggies supplemented by steam

powered brakes acting on the locomotive driving wheels. The log buggy brakes would be applied using a screw

mechanism that pressed a wooden block on to the wheel face to provide retardation. Early log buggies simply

had a wooden wedge to lodge between frame and wheel to act as a brake.

It was the job of the brakeman, who was sometimes also the locomotive fireman, to walk or run alongside the loaded train and

apply or release

brakes as required. It was a dangerous job but a good brakeman and a good driver could act as an efficient

team. Otherwise they could drive each other crazy.

Drivers often stayed with the same bush locomotive for many years and they had to be able to repair their charge

if it should break down in the bush.