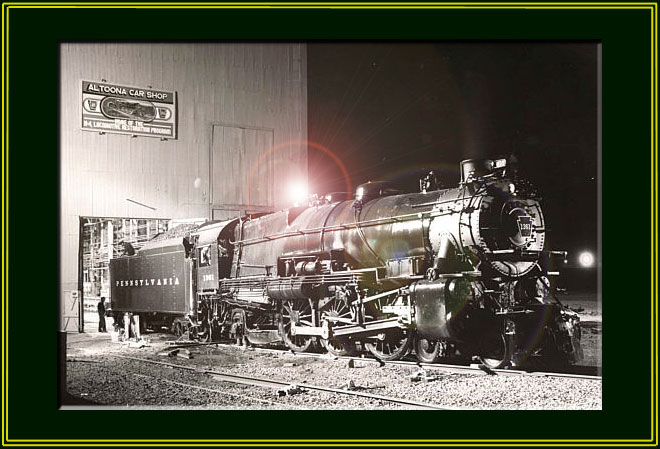

The PRR K-4s #1361

Steam Locomotive Restoration Project

Page 4

(This site is provided as a courtesy of the Altoona Railway Museum Club)

October 8 to 14, 2000

December 11, 2000

On 11 Dec 2000, Ed Wilt (who took 6 weeks leave of absence from his job with Norfolk Southern to work on the K-4) wrote: "Since my arrival at Steamtown to work on the K-4 the following has been accomplished:

1) Lower portion of the front flue sheet has been put in place and all holes for the flues and superheater flues have been ground to a round shape at the areas were they had been welded. Also all flue holes have been polished for upcoming installation of the flues and superheaters.

2) All waist sheets have had all holes welded and reamed to proper size. I have machined approximately 120 tapered bolts that will be used to secure the waist sheets to the T-irons on the boiler. Have approximately 40 more bolts to machine.

3) T-irons have all had the holes welded and reamed out to proper size and have installed 3 to date.

4) I have threaded approximately 50 feet of staybolt rod for the firebox stays.

5) All of the spring equalizer pins have been degreased and sandblasted. The spring equalizers have had all the old bushings arc gouged to remove them and all holes have been ground to accept new bushings. Also the areas where the new bushings will be installed and spring hanger pockets have all been sandblasted for final welding and grinding.

6) New belly plate wash outs have been machines and the old ones have been removed and all holes for attaching the belly plate washouts have been welded and reamed to proper size.

7) I have dismantled cleaned the injectors and sandblasted the main bodies. They have been temporarily been reassembled and are ready to be soaked in Muratic Acid to remove the scale.

8) All driving box shoes and wedges have been degreased and cleaned for inspection, repair and/or replacement.

9) All driving box binders have been identified and placed in proper positions.

10) Holes in the firebox for the replacement flexible stay bolts have been reamed and threaded.

11) Boiler expansion slides have been dismantled. New slide plates have been fabricated and new tapered bolts machined. The expansion slides have been reinstalled.

12) Both pistons have been removed from the cylinders and all rings have been degreased and sorted into boxes for inspection and reinstallation.

13) Frame has been leveled in preparation for future tramming.

14) I delivered the smoke stack to Clearfield Machine to have a new one cast and finished.

Still have another week to go. Will supply further update at the completion of my time here. All for now. Ed." (posted 12-19-00)

January 27, 2001

From: G. Wayne Laepple (via PRR Talk)

Subject: K4s report 1-27-01"Saturday was a very frustrating day for all concerned. Jeff wanted to complete riveting the new front flue sheet to the boiler shell. Dave Goodheart of Goodheart Video Productions was there to record the hot riveting work for a new video he's working on. Walt and I got things started by firing up the rivet furnace, and then we cut 6 rivets to size. Meanwhile, Jeff was polishing the edges of the holes in the boiler shell where the rivets would be seated. You will recall from earlier reports, that when we are doing rivets, four people are needed to do the job -- but today we only had three. This meant that I had to heat the rivet, then carry it up into the smokebox and insert it into the hole so that Walt and Jeff could form it properly. Normally, I would pass the rivet to a "sticker" who would insert it into the hole. Anyway, we heated one rivet and got it done without any trouble. Then we had to add a section to the scaffolding so that Jeff could reach two rivets at about the 3 o'clock position. This is where the trouble started. The next rivet was heated, and I knocked the scale off it and hustled it into the hole. Walt put the buck on it and started hammering, as did Jeff. Unfortunately, due to the distance of the scaffolding from the boiler, Jeff could not bring enough of his weight to bear on the rivet as he was driving it, which caused the rivet shaft to simply bend, rather than forming properly. Since I had another rivet in the furnace, we decided to try the next one, after we laid a plank from the scaffold over to the engine's frame to let Jeff get closer. But again, the rivet head did not form properly.

The problem is that the holes in the new flue sheet are the proper diameter for the rivet, but the holes in the boiler shell are hogged out from who knows how many times of rivets in and out. The shaft of the rivet is not held tightly enough to allow the metal to be expanded evenly and form into a mushroom shape. At that point, Jeff decided it was time for lunch, to which Dave Goodheart generously treated the three of us. After lunch, we cut 10 more rivets. Jeff, meanwhile, cut the heads off the two malformed rivets, and then, using a rivet hammer, drove the rivets out. We tried one more at the 3 o'clock position, but we had the same problem. Then Jeff decided to work on the bottom of the boiler. The five rivets at the very bottom of the boiler's radius require a somewhat different, nearly flat head because of a clearance issue with the engine brake cylinders which are just beneath the boiler shell. The problem here is that the rivets must be formed almost directly overhead. So Jeff needed to wear a leather jacket, a hard-hat, and face protection. Even so, little hot bits of the rivets rained down on him as he drove the rivets. We got started OK, but then on the second rivet, Jeff lost the die from his hammer down into the pit. So that was another rivet that had to be replaced.

We finally did get the five rivets in, but Jeff decided to call it a day when a hot piece of slag got behind his face shield and burned his cheek. Even though we heated and drove only 10 rivets, it took most of the day -- remember -- we had to replace three of them! Very frustrating. But Dave Goodheart seemed pleased with the video he had recorded. Since my last trip in early December, Jeff has three of the waist sheets permanently in place, and he's been working in the firebox building up the side sheets with weld where the arch bricks will rest. Other shop work observed includes repairs to the pilot truck of 2317, which was damaged in a derailment in mid-December. Scaffolding has been placed around 26, which will have its crown sheet replaced this year. 3254 is still in the paint shop awaiting final paint. My next trip will probably be in mid-February. As usual, questions, comments, suggestions solicited. Cheers -- Wayne"(posted 2/6/01)

02/13/2001 News Announcement

Good news for the Altoona Railroaders Museum. Plans were announced yesterday for a Roundhouse to be constructed at the museum to house the K4 #1361 Steam Locomotive when it returns to Altoona. State Representative Rick Geist was on hand to announce that Governor Ridge awarded 450 thousand dollars to be used towards the construction. The first phase should be completed by December 1st, which is the same time the K4 should be returning to Altoona. Altoona.Com

(Railfest is a trademark of Railroaders Memorial Museum, Inc

. The logos for the Altoona Railroaders Memorial Museum is a trademark of the Railroaders Memorial Museum, Inc.

Photographs are by Chris Behe unless otherwise noted)