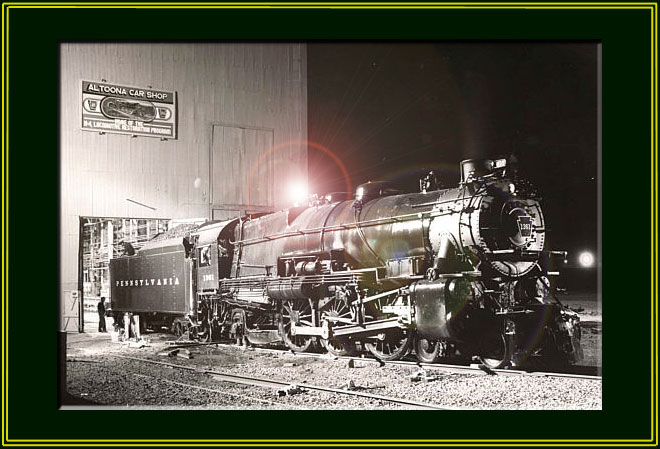

The PRR K-4s #1361

Steam Locomotive Restoration Project

Page 26

(This site is provided as a courtesy of the Altoona Railway Museum Club)

July 2006 K4 Update

These photographs were taken between January2006 and July 2006 by Charles Cantrell, 1361 Volunteer.

|

The tender draft box area had to be built up and reworked due to deterioration. |

The tender end sill had to be completely remanufactured due to rust and deterioration. |

More boiler braces are brought out of storage for sandblasting and repairs if needed. |

Brake rigging. |

|

Both tender trucks required spring hanger gusset repairs due to excessive wear. This is the same area show in photo 36 after repairs. |

Work continues on the tender frame. |

A view of the newly fabricated valve gear link block. Here you can see the lubrication passages that had to be machined into the blocks. |

Another view of the link block. |

|

The stocker elevator pipe assembly is brought back into the shop for initial fitting to the locomotive frame. |

The elevator pipe assembly has been brought over next to the locomotive frame prior to attaching it to the locomotive. |

The elevator pipe support is temporarily attached to the mud ring and back-head to check for proper fit and alignment prior to attaching the elevator pipe. |

A view of the elevator pipe support from the rear of the locomotive frame. |

|

One of four bolt mounting hole that required filling in due to excessive ware. The hole will later be drilled to the proper size prior to final assembly. The welding was performed by volunteer Charles Cantrell. |

Close up of another weld. |

The inner door sheet (back sheet) and back-head are remounted on the locomotive in preparation for fabricating a new boiler wrapper sheet section. |

The old back-head has been resurrected as a jig to fabricate the new roof sheet and back-head patch section. You can see, what will become, the new roof sheet section mounted in the jig prior to forming. |

|

Contractor Bill Frederickson starts the initial heating of the sheet while Walter Elvidge slowly applys tension on the chain host to start the bending process. |

Volunteers Chad Frederickson and Charles Cantrell keep the heat on while Walter Elvidge continues to apply tension with the chain hoists. |

Bill holds a flattening hammer while Jeff Kemmer swings the sledge. The continuous movement and positioning of the flattening hammer and the subsequent blows of the sledge slowly start the sheet to form to the desired shape. |

A side view of the previous process. |

|

The shaping process continues. |

Bill directs Walter while Chad keeps the heat on the opposite side of the sheet. |

The heating process continues. |

Chad and Jeff heating the sheet while I apply tension to the chain hoists. |

|

After a round of hammering, Jeff takes over torch duty from Chad. Chad will now take over the hammer while Bill continues to hold the flattening hammer. |

Chad and Bill working as a team while I continue to keep tension on the chains. Walter and Jeff take a few moments break from the extreme heat. |

A view of the completed sheet. It has been trimmed initially to fit the location where it will be installed. |

A view from the engineer’s side of the sheet. |

|

The pony truck is rolled back into the shop for additional repairs. |

The pony trucks transom bushing locations were deteriorated. The transom required machining to accept new bushing and pins. Here you can see the completed machining. |

A close up of the completed machining. New bushings and pins will be fabricated in the machine shop. |

Volunteers Tom Diehl and John Fauzio taper ream rigid staybolt locations on the inner throat-sheet due to excess thread wear. The holes will later be welded then drilled and threaded to the correct size for the new staybolts. |

All, Thanks for enduring the delay on website updates. Future updates will be posted intermittently. Regards. The Webmaster.

Stay tuned for additional photographs of the PRR K-4s #1361 Restoration!!