#4483 in the 2010's |

September 2016

October 2016

|

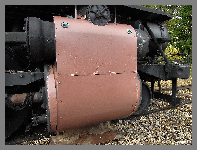

On the 17th, we bolted the two pieces of the cylinder jacket sheet metal to the locomotive. The 3/8" speed nut clips on the lower sheet lined up perfect with the holes in the top sheet. All 20 threaded holes got a dab of "Permatex® Anti-Seize" before the stainless steel bolts were screwed in place. Thanks to Mike M. for the use of his pneumatic offset flange tool. |  |

June 2017

| Over the summer of 2017, work continued on the fireman's side cylinders using the same proceedure we used on the engineer's side. All the old bolts were drilled out and the holes re-tapped for the new 3/8" stainless steel bolts. Both the inside and the outside of the cylinder cover was primed and then the inside painted. The following week the cover was bolted on. |

Spring - Summer 2018

| All efforts during 2018 were turned to getting Buffalo Creek #43 ready to run. Everyone worked on last minute details getting the diesel engine ready to start. This left no spare hands to work on #4483. |

Spring 2019

Web Site Hosting by TRAIN WEB

The WNYRHS, Inc. 100 Lee Street, Buffalo, NY. 14210 is an independent organization and has no affiliation with any other local or national group.

The Society is a fully qualified organization under 501 (C) (3) of the Internal Revenue Code and all donations to the Society are tax deductible.

©Copyright 1999 , WNYRHS Inc. all rights reserved