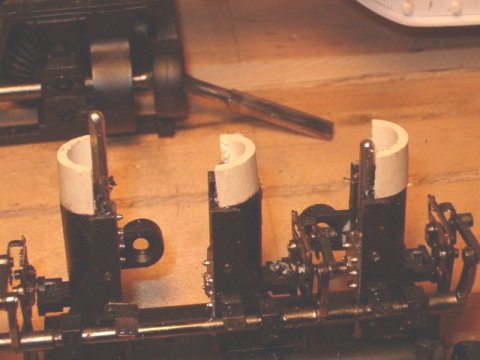

Fig 17 |

Fig 18 |

| With the cylinders done, I turned

my attention to the rest of the Bachmann engine assembly. With an

Xacto razor saw I carefuly cut off the old cylinders, a beheading if you

will. Figure 17 Then I extended the barrels that hould the

crsshead guides with appropriate lengths of PVC water pipe. Figure

18. Holes were drilled in the bottom of the cylinders to accept

the valve and piston rods, and the new cylinders secured on top of the

barrels.

Adequate lubrication was applied

to make sure that nothing locked up and the engine was tested by turning

the crank shaft til all the glue was dry.

|

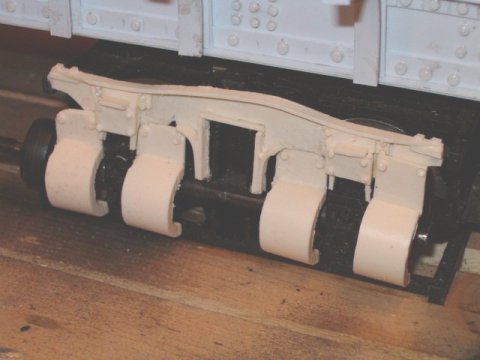

Fig 19 |

Fig 20 |

With the engine securely in

place on the frame I addressthe driveline. the stock drivelines

were way too short. All I can say is thank goodness for K&S square

brass tubing. A piece of telescoping tubing was slid onto the

mal portion of the sliding joint to upsize it and lengthen it. This

is just a friction fit, but is quite tight. The female section took

a bit more work.

First I cutoff the old sleeve almost completely off, then I built up the interior of the brass sliding sleeve so that a brass rod soldered inthe end would fit in the remains of the original sleeve. I then drill though this rod and pinned it in place with a brass nail and a dab of CA. Figure 21 With that much fiddling

accomplished (I had really expected the drivelines to be much harder than

that to accomplish) I applied the cast steel castings to the trucks.

Te result was instantly a completely different look!

|

Fig 21 |

Fig 22 |