|

Steam Locomotion in the 21st Century The Recent History of Steam Locomotive Development |

updated 7 February 2022

The Donna Christina Railroad in Brazil was a coal-hauling railway which was very famous among U.S. railfans for its use of heavy duty, relatively modern design 2-10-4 Texas type locomotives, built in the U.S. by ALCO and Baldwin. These engines worked for many years hauling heavy coal trains from mines to a power plant in Brazil. By the 1980's, the boilers of these engines had worn past the point of being repairable (one is reported to have exploded). Several solutions were considered, including importing new boilers from elsewhere, but finally similarly sized European-built 2-10-2 locomotives were brought in from Argentina to replace the 2-10-4's based on the suggestion of famed steam writer A. E. "Dusty" Durrant.. The 2-10-2's were converted from oil to coal firing and placed into service.

While the 2-10-2's evidently performed well, even this railway, like the rest of the world, began to look into dieselizing its trains. A major complaint raised about the coal-burning steam locomotives was the smoke, cinders, and soot they discharged. At some point, Ing. Porta, whose Gas Producer Combustion System provided a proven way of dealing with these problems, was contacted and brought in as a consultant for the railway.

Under Porta's supervision, a Jung 2-8-2 was initially fitted with a Lempor exhaust system and GPCS firebox near the end of in 1989. Based on the success of this locomotive, 2-10-2 number 203 was similarly modified in 1990, followed by other 2-10-2's in 1990, 1991, and 1992 (4 2-10-2's total). The following photos, generously provided by Sergio Romano, show the results of this work.

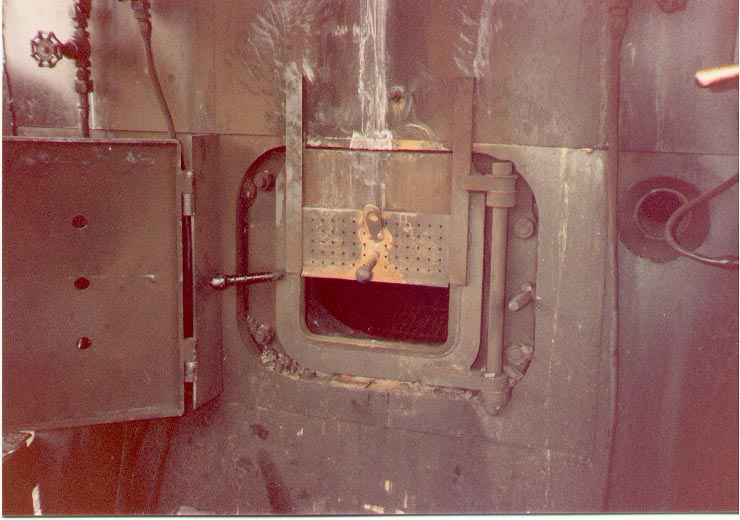

This photo shows the vertical sliding firedoor fitted to one of the locomotives. To the left, a hinged guard can be seen which would have helped reduce noise and glare in the cab between periods of firing. To the right of the firedoor, one of the secondary air admission ducts which admits over-fire combustion air above the thick coal bed can be seen.

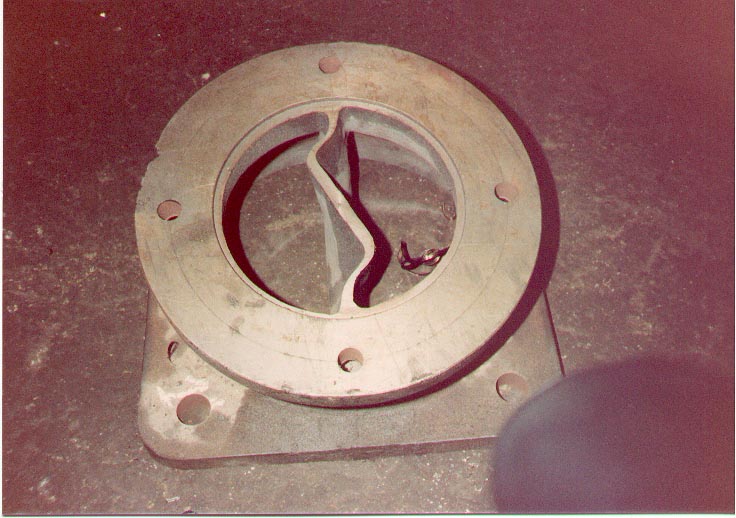

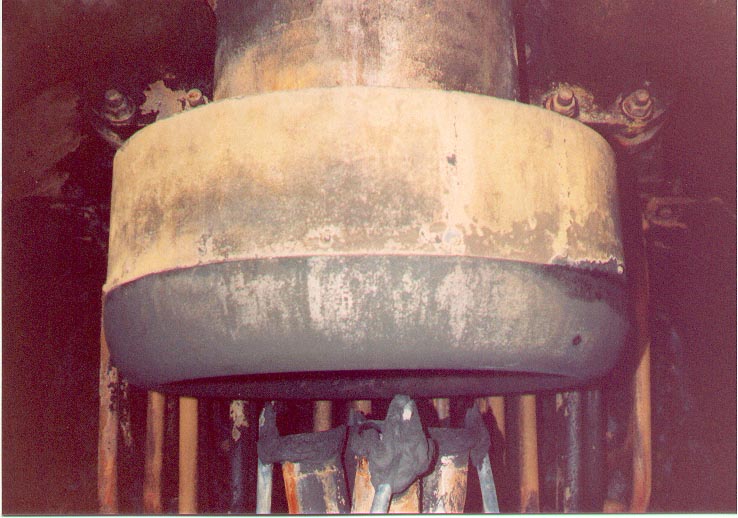

The above photo shows the base for the steam exhaust nozzles called the "Kordina". The "s" shaped center divider keeps the exhaust from the two cylinders separated until it enters the steam nozzles, and imparts rotary motion to the steam blast in order to promote faster mixing of the steam with the combustion gases, which increases the efficiency of the system.

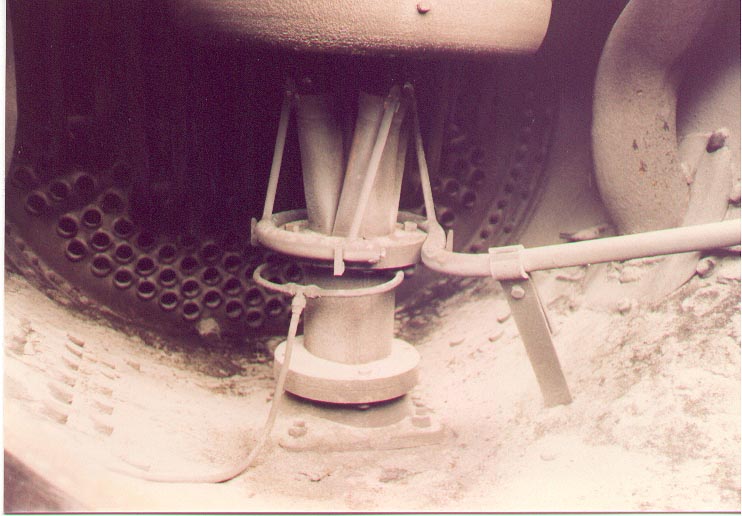

The above photo shows the bottom of the smokebox, with the assembled Lempor exhaust system in place. The base of the stack can barely be seen at the top, while two of the four Lempor exhaust nozzles show along with the blower asembly.

The above photo provides a close-up view of the

Lempor steam nozzles, as well as the unusual extended steam blower

nozzles. Note that both sets of nozzles seem to be set skewed so

as to provide a rotary motion to the exhaust flow. This

arrangement was planned for the Lemprex exhaust system, which

Porta was working on in his later life.

The above photo shows the bottom of the Lempor exhaust stack (chimney) with its carefully radiused inlet to ease the flow of exhaust gases up the chimney. The superheater units can be seen in the background.

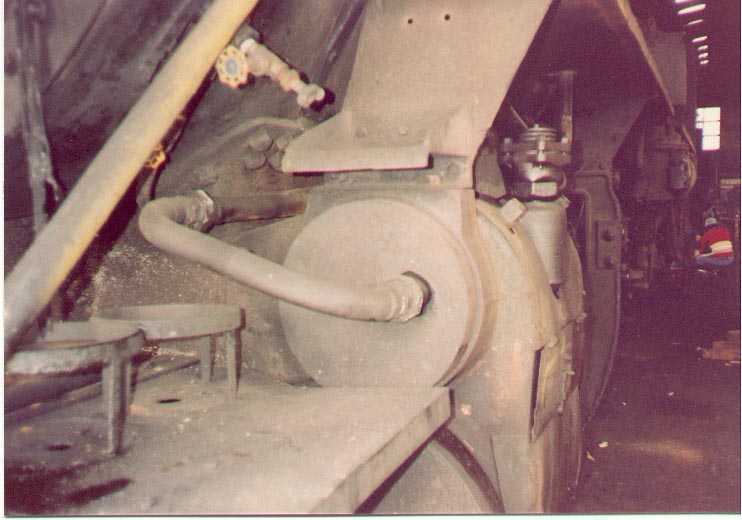

The above photo shows the front of the fireman's side cylinder. The curved pipe near the center of the photo feeds exhaust steam from the cylinder's steam chest back to nozzles below the grate under the firebox. This steam slightly cools the coal fire (reducing the formation of clinkers) and promotes the production of producer gas which is then burned inside the firebox.

Porta with Sergio Romano in front of number 210, one of the modified 2-10-2's. Note the angled Lempor Exhaust chimney (oriented so as to provide optimum steam flow and to provide clearance for the superheater header within the smokebox).

Jung 2-8-2 No. 4, fitted with GPCS firebox and Lempor Exhaust, during light-up test showing no smoke. A conventional coal-fired steam locomotive would be producing vast clouds of black smoke under these conditions.

Jung 2-8-2 No. 4 on the left, starts a train while producing only a light haze of smoke. The conventional locomotive in the background, produces typical heavy black smoke.

Unfortunately, the Teresa

Christina's steam operations had almost completely stopped by

2003. At that time, the Jung 2-8-2 shown above is still in

operation in Rio Grande do Sul state, on the "Wine Train", a

tourist train between the cities of Bento Gonçalves and

Jabuticaba. Unfortunately, the only part of the GPCS remaining

are the firebox orifices for the secondary air. In Tubarão the

modified 2-10-2 locomotives remain as they were when operations

stopped, rusting away. One of the 2-10-2's was briefly

returned to service for discharge of coal trains in

Eletrosul yard (coal-fired electric power plant) at Capivari,

when traffic was increased due the lack of rain (the

hydroelectric generation plants were almost in

collapse) about two years ago, and Eletrosul needed to

produce extra electricity. After this, it was sporadically

lighted for a tourist train.

A recent entry on the ratings

site "Tripadvisor" appears to state that in November 2019, the

railway operated trains with a dead steam locomotive up front,

pushed by a diesel behind.

Many thanks to Sergio Romano of Brazil for providing these excellent photos and information.

Return to The Ultimate Steam Page