Text of ACE 3000

Technical Paper ASME No. 82-RT-2 Originally

published by:

|

| David

A. Berkowitz Manager, System Analysis & Control JAYCOR Woburn, MA |

William

B. Benson President American Coal Enterprises Akron, OH |

William

L. Withuhn Fellow, Smithsonian Institution Washington, DC |

This paper describes the ACE 3000, a newly poposed coal-fired steam locomotive. As a basis for understanding the innovative aspects of its design, the state- of-the-art that was reached at the close of the steam locomotive era about thirty years ago is reviewed. Subsequently, railroads converted from steam power to diesel-electric. Engineering design criteria are suggested for a new generation of coal-fired steam locomotives that would meet today's environmental, operational, and economic constraints, and compete effectively with the diesel. The ACE 3000 satisfies the new constraints and promises to free the railroad industry from dependence on liquid fuel resources. Its performance, operational, and design features are described.

INTRODUCTION

For approximately forty years, railroad motive power requirements have been met by the diesel-electric locomotive. The diesel has proven to be reliable and efficient; it has significantly increased railroad productivity in hauling a steadily increasing amount of tonnage. Railroad operating, maintenance and service procedures have evolved that are adapted to its unique characteristics; many are based on concepts of modularity and standardization. For example, diesel locomotives are operated in multiple unit lash-ups, with a single operating crew, to provide the aggregate power required to move a train on the desired schedule. In maintenance and servicing shops, component interchangeability and standardization insure minimum loss in unit availability, even when major repairs are required.

A new element in diesel locomotive operation, however, is cost of fuel oil which has risen dramatically in the last three years to become the largest cost element in diesel locomotive ownership (1). the modified economic picture has motivated exploration of alternative fuels for the diesel, as well as totally different types of locomotives that do not use fuel oil as their energy source (2). One such class of locomotives are those that employ direct combustion of coal. Is it practical to develop a new coal-fired steam locomotive that would compete favorably with today's diesel-electric with respect to operation, cost, reliability, and environmental impact?

This paper describes the ACE 3000, a locomotive that has been proposed for near term development. It is a new coal-fired steam locomotive that promises to fulfill requirements of the railroads in what has become a new operating era.

BACKGROUND

In the coal-fired locomotive era that ended in this country approximately thirty years ago, environmental acceptability, engine, low maintenance operation, and train-track dynamics did not have the priority that they do today. Consequently, the coal-fired steam locomotive of that period is now unacceptable; it polluted, was inefficient, required frequent maintenance, and damaged track. Nonetheless, it is helpful to review state-of-the-art reached in steam locomotive development as guidance for engineering design of the next generation.

Emissions

The problem of excess smoke was inherent to coal-fired reciprocating steam locomotive design. Complete carbon utilization was impossible because of uncontrolled draft, high velocities of primary air through the firebed, and uneven firing. At higher boiler outputs, carbon loss increased as unburned fuel was drawn out the stack. At full output, carbon loss could reach 50%, resulting in a rain of cinders and particulates. Heavy emissions of NO x, CO, SO2, small and large particulates were unavoidable. In addition, water contaminated with ejected cylinder lubricant and boiler treatment chemicals was released as steam to the atmosphere and as water from boiler blowdown.

At the end of the steam era, some experimental steam turbine locomotives were constructed, notably by the Norfolk & Western and the Chesapeake & Ohio railroads (3). Although a remotely fired, high pressure boiler was installed on the N&W locomotive, no basic change in emission characteristics was made. Combustion was still at relatively high temperature with a high level of induced draft, resulting in high carryover and loss of unburned fuel.

Engine Efficiency

Efficiency most advanced reciprocating steam locomotive developed in the United States in the 1950s was a freight locomotive with compound steam expansion in two separate engines; it achieved a drawbar thermal efficiency of 8% (4). The more typical two cylinder locomotives with simple expansion achieved drawbar thermal efficiencies of only 5 to 6%. The inefficiency was from poor combustion and engine losses. Engine losses derive from: flow loss due to excessive pressure drops incurred from boiler to cylinders (or boiler to turbine); loss, or inefficiency due to incomplete expansion; and thermal loss within the cylinders (or within the turbine)

Designers strove to streamline steam passages and valves, following principles pioneered by A. Chapelon on French railways in the 1930s (5). Expansion losses in reciprocating engines were reduced by using higher expansion ratios (as in compound cylinders) and valves capable of shorter cutoff (such as poppet vales), and reducing backpressure in the steam-induced furnace exhaust (as with Kylchap and Giesl exhaust devices). Thermal losses within cylinders or turbines were reduced by raising superheat temperatures. Reciprocating locomotives were limited to steam temperatures of 750 degrees F due to breakdown of cylinder lubricants; turbines were not so limited.

Drawbar efficiencies of the best experimental turbine locomotives were no greater than 10 to 12% under controlled operating conditions. In normal service, the steam turbine was often no better than a compound expansion reciprocating locomotive; turbine efficiency fell off rapidly at part load, while the piston engine kept its efficiency over a wide range of operating load and had superior response to transient demands.

Maintenance

Of all traditional steam locomotive characteristics, the high level of maintenance was its major failing in the eyes of railroad managers.

Poorly treated water was endemic to railroad operations through the 1950s. Scale formation was rapid and always a serious limitation; monthly washout was required. Some railroads washed boilers weekly or daily. Despite this precaution, scale formation limited boiler pressures; 300 psi (14.4 kPa) was all that was deemed safe in a firetube boiler, and 600 psi (28.7 kPa) in a watertube boiler. Stress due to scale was a major source of boiler and firebox cracks.

High carryover of cinders and unburned coal eroded flue tubes, boiler sheets, and superheaters. Such carryover also prevented the use of economizers. Maintenance of fireside surfaces was difficult and time-consuming, often entailing replacement of flues and superheater tubes.

The riveted, firetube boiler with threaded staybolts was used from 1830 to 1950, with little change except in allocation of area between flue, furnace, and superheating surface. All-welded boilers were explored, but inability to insure safety of each weld prevented widespread adoption. Watertube boilers were tried to attain higher pressures. Their construction was relatively complex, however, and the hostile operating environment with frequent shocks up to 15 g put great strain on the boiler resulting in tube leaks. A great virtue of the firetube boiler was its inherent strength; the heavy barrel forms an important structural member of the boiler-frame unit, permitting the whole locomotive and boiler to survive normal duty and even severe derailments. The riveted seams and threaded staybolts, however, required the greatest percentage of maintenance hours compared to any other locomotive component.

The air/gas and water/steam pathways intersect in conventional steam locomotives; exhaust steam induces furnace draft. When the throttle is closed a partial vacuum draws flue gas into the cylinders carbonizing the lubricant and causing rings to stick and lubrication to fail. Close tolerance rings to reduce piston leakage were impossible. Reboring cylinders was a necessary and time-consuming requirement.

Steam turbines were also subject to high maintenance, often due to contaminated steam.

Although the direct-connected piston drive was simple, engine maintenance was high, requiring axle realignment, adjustment of rod and axle bearings, adjustment of bearing boxes in their frame guides, and valve gear resynchronization. Roller bearings, developed in the 1930s, solved many of the lubrication and realignment problems. However, other parts of the drive still required open lubrication; self-lubricating materials were unknown.

Train-track Dynamics

Track Dynamics two-cylinder reciprocating drive is inherently unbalanced. Either revolving mass can be balanced, or reciprocating mass, but not both. Cyclic vertical loads increasing with speed were imposed on the track with every wheel revolution damaging rail and degrading track alignment.

High-speed steam locomotives were successfully designed, however, utilizing guiding trucks and lateral restoration devices on driving axles to reduce and cushion lateral flange forces. Operation at speeds up to 110 mph (180 km/h) was common, often with more stability than present diesel locomotives.

Fully-balanced four-cylinder engines common in European practice, but were never popular in the United States. Such locomotives incorporated two cylinders mounted internally with crank axles, which were relatively inaccessible for maintenance.

Anti-slip and adhesion control on conventional steam locomotives was impossible because of manual throttle valve operation and manual adjustment of control valve timing. Successful slow-speed, heavy drag performance of steam locomotives depended on the engineer's skill. Slow speed performance was a primary virtue of diesel-electric locomotives, limited only by amp-hour restrictions on traction motors to avoid burn-out. This limitation remains today. A reciprocating steam locomotive has no such power limitation, and within the adhesion limit can operate continuously at full power at both high and low speeds with high reliability.

DESIGN CRITERIA FOR A NEW COAL-FIRED STEAM LOCOMOTIVE

For a new locomotive to capture a portion of the replacement or growth market, it must result in reduced operating cost and improved performance with respect to modern diesels, and be otherwise acceptable to the railroad industry. Industry acceptability involves many factors, both economic, technical, and psychological.

The approach taken by American Coal Enterprises seeks to develop a locomotive whose performance characteristics would be operationally compatible with existing railroad practice, and whose impact would be minimal in terms of new facilities required to service, maintain and repair it. major design criteria include environmental acceptability, efficient use of water and coal resources, reliability, and a two year development period. The criteria are summarized in Table 1 and will be discussed individually below.

Other major design criteria include environmental acceptability, efficient use of water and coal resources, reliability, and a two year development period. The criteria are summarized in Table 1 and will be discussed individually below.

Table 1

|

Criteria for New Coal-Fired Locomotive |

|

Environmental Acceptability

Acceptability standards applicable to a coal-fired locomotive do not currently exist. Nonetheless, in keeping with the current sensitivity to environmental issues, acceptability of a new locomotive could be strongly related to its environmental impact. An important design criterion for a new coal-fired locomotive is that it be perceived as being "clean," and that its emissions of NO x, S02, particulate matter and discharged solids be within what can reasonably be anticipated to become future limits for sources of this type. Heat input to a locomotive is much closer to 50 x 106 BTU/hr (14.6 MW) than to 250 x 106 BTU/hr (73.2 MW) which is the minimum size of stationary power plant for which standards exist. In all probability, standards for small, mobile sources will be less stringent than for large, stationary sources. However, in the absence of emission standards, conservative design goals for a coal-fired locomotive can reasonably be set at current levels for large stationary plants.

The noncombustible ash component of coal can no longer be casually discharged as cinders along the right-of-way; it must be held on board for proper disposal at a locomotive servicing facility. That fraction of the ash which is entrained in flue gas as fly-ash must fall within the particulate emission standard, as well as any burning coal particles or glowing cinders.

A secondary consideration in setting design goals for a coal-fired locomotive is that it having less environmental impact than diesels for which emission of unburned hydrocarbons and nitrogen oxides (NO x) emissions pose potential environmental problems. Unburned hydrocarbons emission is extremely low in coal combustion, and NOX can be kept well below stationary standards by selection of an appropriate combustion scheme (see below).

In the process of combustion, sulfur in coal or in diesel fuel appears as sulfur dioxide (SO2) in exhaust gases. In the absence of an emission standard for coal-locomotives, a reasonable goal for SO2 emission level is that which is currently achieved in large stationary facilities. Such levels can be achieved by burning "compliance" coals whose weight-percent of sulfur is in the 1-2% range. Even assuming total conversion of all railroad locomotives to coal-firing, the total requirement for coal will only be a small fraction of all the coal burned for industrial purposes or power generation, so that adequate supply of low sulfur coal does not appear to be an issue. Once the use of coal as a transport fuel has been reestablished, fluidized bed combustion techniques could advantageously be developed for locomotive applications if S02 emissions or excessive cost of low sulfur coals become significant problems (2).

Working Environment

Environment working conditions of an old steam locomotive are unacceptable today. A new coal-fired locomotive must provide a safe environment without occupational hazard, and provide other amenities for crew comfort.

Efficient Use of Resources

Use of Resources for supplying coal and water to steam locomotives have been entirely dismantled. Furthermore, the old coaling towers would now be unacceptable because of fugitive dust released in loading and unloading operations.

A coal-fired locomotive should have an operating range such that the required number of coaling and watering stations is minimized. A minimum range would be approximately every 500 miles (800 km), the distance at which current operating rules require a visual inspection of the entire train; refueling could be accomplished during the inspection. More advantageous, however, would be an operating range that would permit refueling to be done at major service or maintenance facilities located either at terminal points or enroute.

Efficient conversion of heat energy in combustion into tractive effort is an important design goal that will reduce the amount of coal required, as well as reduce the required number and size of facilities that must be provided for locomotive servicing.

Because of the abundant supply of inexpensive coal years ago, poor combustion efficiency was not a major drawback. In addition, there were no compelling reasons for streamlining of steam pathways and optimization of the expansion cycle; these were not major design objectives and the "brute force" approach was acceptable for many years. Efficient use of resources has much greater importance today. Current diesel locomotives achieve efficiencies greater than 20% at the drawbar in normal operation, and that is certainly a reasonable design objective for coal-fired steam. However, because the cost of oil is several times the cost of coal per energy unit, it is possible to trade-off slightly lower efficiency when burning coal in order to shorten development time and produce a more rugged and reliable machine. It would still provide a far more cost effective locomotive (2, 6).

In a coal-fired steam locomotive, use of a condensing or partially condensing steam cycle can significantly reduce water consumption and increase locomotive range between water stops. There are additional benefits associated with reduction in cost of water treatment and waterside maintenance. Use of treated water in a fully condensing cycle with makeup water kept to approximately 10% for auxiliary use, boiler blowdown, etc. would minimize required water facilities and insure low maintenance requiring no more than yearly washout (7).

Reliability; Low Maintenance

The goal for locomotive availability is at least 90% in normal service. To achieve or surpass this goal will require rugged and reliable equipment capable of continuous normal operation in the severe railroad environment. Designs must employ standardization and modularization techniques to the greatest extent to facilitate service and repair operations. Preventive maintenance on a routinely scheduled basis is preferable to waiting for failures to occur.

The need for low maintenance also applies to track maintenance. Desirable characteristics of a locomotive with respect to track interactions are balanced drive, balanced wheelsets, and good curving performance with minimum hunting. The most successful locomotive is one which will not cause excessive wheel or track wear, nor result in widening of the gauge or misalignment.

Compatibility with Railroad Operating Practice

Railroad operations today are committed to the diesel engine (with the exception of a small fraction that is electrified). Any new locomotive that is introduced by the railroads will require some modifications in current operating practice. The greater the departures from current practice that a new locomotive will require, the less likely it is that the new locomotive will be adopted. Its advantages must be sufficiently compelling to compensate for the difficulties encountered bringing it into service. In conceptual design of the ACE 3000, a high value was placed on railroad acceptability; consequently, compatibility with existing practice influenced many aspects of the design.

At the present time, individual units of about 3000 horsepower (2.2 MW) are the most common; this seems to be an optimum size that is suitable for several types of duty and satisfactory for all railroads. For greater tractive effort, several units are combined in a multiple unit lash-up under control of a single engineer in the lead unit. Additional units can be added at mid-train or at the rear for helper and pusher service and controlled by radio dispatch from the lead unit. The units are about 60 feet long and spacing and layout of equipment in shop facilities has adapted to this length. Control of the diesel is with a single, multiple-notch throttle lever. The units are fully bidirectional and need only be turned for safety purposes associated with crew visibility.

With respect to maintenance and, many diesel engine components are standardized and readily replaceable. For example, cylinders have replaceable liners and even individual cylinders can be replaced. Individual wheelsets and traction motors can be dropped out and replaced. Wheels can be trued in place on the locomotive. In some diesel locomotives, the manufacturer maintains a great degree of parts interchangeability even among succeeding models in the product line.

ACE 3000 LOCOMOTIVE

The ACE 3000 is a coal-fired reciprocating steam locomotive that will burn coal in an environmentally acceptable manner, three times as efficiently as steam locomotives previously built in the United States. It is fully compatible with present railroad operating practices. In general purpose service, the operational and performance characteristics are at least equivalent to those of the most modern diesel locomotives. It has been engineered for maintenance in existing shops with minimal additional facilities. Requirements for coal and water servicing facilities have been minimized by the unique coal pack and condensing steam cycle.

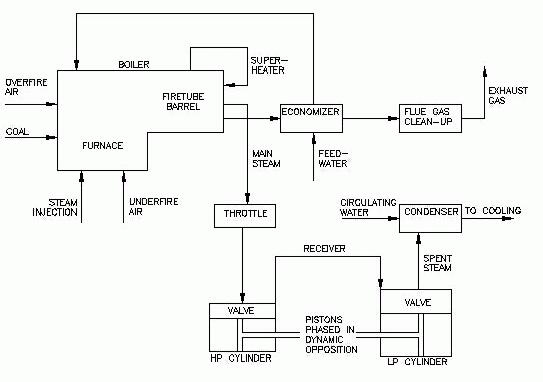

The locomotive consists of a power unit and support unit as shown in Figure 1 which are drawbar-coupled back-to-back with each unit having a cab in front. The power unit contains the furnace and combustion system to burn coal in a two-stage gas-producing mode, ash collection and storage, gas clean-up and exhaust, boiler and steam generator, steam engine, condenser and control cab. The support unit contains the storage area for enclosed modular coal packs and stoker-screw, water storage, heat transfer assemblies and fans for cooling circulating water, and control cab. A simplified flow diagram for air/gas and water/steam pathways is shown in Figure 2.

The Steam Engine

ACE 3000 is powered by a 4-cylinder reciprocating steam engine incorporating an opposed-piston arrangement that is inherently balanced dynamically at all speeds. The steam expansion cycle is compounded: two high pressure cylinders exhaust into two opposing low pressure cylinders with all cylinders sized for equal thrust. Spent steam is further expanded through a small turbine for auxiliary power, then condensed, cooled on the support unit and the recovered is recycled through the boiler and generator.

Piston thrust is transmitted to the wheels by main rods. There are four of drive wheels coupled into a single by pairs of connecting rods between each pair of adjacent wheels. The rods between Nos. 2 and 3 drive wheels are mounted internally on crank axles. This arrangement locks the pistons in phased opposition and automatically balances the reciprocating mass at all speeds.

The pistons are fully supported within the cylinders by extended piston rods and are designed for a precision fit within easily replaceable cylinder liners. The pistons have multiple diesel-type rings for low leakage and long wearing life. The cylinders themselves are jacketed with saturated steam at boiler pressure to reduce heat loss from the steam cycle and insure a uniform wall temperature that is within the range of available cylinder lubricants. Valves controlling steam flow incorporate improvements which reduce pressure loss.

The Furnace

The ACE 3000 gas-producing combustion technique was selected for its low carbon loss and favorable environmental characteristics. The gas-producer furnace burns coal in two stages. The coal is mechanically distributed across a thick fuel bed supported on an oscillating shuffle grate. In the first stage, coal devolatilizes in the fuel bed leaving behind the char component which gasifies. Char gasification is controlled by maintaining air flow up through the fuel bed at less than the amount required for complete combustion and by injection of steam into the air flow to enhance gas production. When burned in this fashion, temperature of the burning coal is relatively low, which facilitates agglomeration and collection of the noncombustible ash component of the coal, which in other combustion processes is discharged to the environment. In addition, the furnace design minimizes gas velocity through the fuel bed and reduces entrainment of fine particles of ash and coal in the flue gas. In the second stage of combustion, remaining volatile components and char gasification products are burned to completion with additional air injected into the furnace above the fuel bed. This type of gas-producing combustion has been employed in steam locomotives in Argentina and South Africa confirming that it is clean and efficient (8). Ash is agglomerated and collected as a residue; there is no smoke; there is no fouling of heat transfer surfaces in the boiler; and coal burns to completion with very little carbon loss. Because of the reduced combustion temperature in a gas producing furnace, emission of nitrogen oxides is also very low. Emission of sulfur oxides can be kept within proposed EPA emission standards by burning low sulfur coal (less than two percent) which is readily available in the quantities required for railroad locomotives.

The gas-producer combustion process is clean, efficient and by its very nature can burn a wide spectrum of coal types from high BTU/low-ash to low-BTU/high-ash types that are found in U.S. coal fields. It is well suited to the locomotive application.

The Boiler

The firebox chamber is confined within the boiler walls. Boiler steam pressure is normally 300 psi (14.4 kPa); structural integrity is maintained by staybolts in accordance with well established locomotive boiler design practice. All stays and seams are welded to reduce maintenance. The firebox transitions into a cylindrical firetube assembly that provides additional surface for raising steam as well as superheat surface. Steam collected from the top of the boiler drum passes through superheater tubes that loop into the firetubes and then return to a main steam collection header. Steam then passes to the throttle and high pressure cylinders.

Feedwater introduced into the boiler is preheated with a small amount of steam extracted from cylinder exhaust. It then passes through a finned-tube economizer where it is heated close to the saturation temperature.

The Steam/Water Flow

The ACE 3000 will be a condensing locomotive. The reasons for this are threefold: to extend the operating range of the locomotive between watering stops, to reduce boiler maintenance, and to improve engine cycle efficiency.

A condensing steam cycle greatly reduces requirements for make up water and thereby minimizes the need for new enroute watering facilities. Water introduced into the boiler is treated to remove dissolved solids and chemical impurities, eliminating waterside corrosion and scale formation in the boiler. The condensing cycle with water treatment makes ACE 3000 boiler maintenance similar to stationary boiler practice which typically requires no more than yearly washout (7). The condensing cycle also improves engine efficiency by reducing back pressure into which spent steam is exhausted and enables the locomotive to derive more cylinder power from the same quantity of steam compared to conventional, noncondensing steam locomotives. Condensing of the steam is by a jet-eductor process which takes place on the power unit and utilizes recirculated water taken from the support unit.

Efficiency

Improvements in combustion efficiency and carbon utilization, increased steam cycle efficiency, reduction of heat losses, care in design of steam pathways to reduce pressure drops, and use of modern computer control techniques contribute to a threefold increase in efficiency compared to conventional steam locomotives.

Measurements of drawbar thermal efficiency on gas-producer locomotives in Argentina indicated efficiencies of 15% in carefully controlled conditions and 12% in routine operation (8). With the addition of a condensing steam cycle and microprocessor control, a drawbar thermal efficiency of 15% in normal operation is indicated for the ACE 3000 after deductions for piston leakage, cylinder wall temperature loss, engine resistance, etc.

Microprocessor Control

In order for the ACE 3000 to operate in multiple unit with other ACE 3000's or with diesels under control of a single operator in the lead locomotive, the ACE 3000 will be equipped with a computer control system implemented with microprocessor-based hardware. The control system will respond to the operator's throttle and dynamic braking commands and automatically trim and adjust coal, air and steam flows, and cylinder cut-off, in accordance with speed, load, and emission control requirements. The control system will insure that the ACE 3000 is optimally controlled under all operating conditions and will enable the locomotive to respond in accordance with various operating strategies which are preprogrammed such as maximum adhesion at low speed, maximum fuel efficiency, or minimum environmental emission.

In addition, the control system will monitor and display furnace, boiler, and engine performance parameters on a cab mounted display and alert the operator to unusual or emergency conditions in any of the ACE 3000 locomotives in multiple unit. In the event of an unsafe condition or actual emergency, the control system will reduce load to a safe level or shut down the locomotive unit.

An inherent characteristic of the control system is rapid response time which gives the ACE 3000 its capability for effective adhesion control. When combined with fast acting actuators for throttle, cut-off and relief valves, control actions will occur within the time of a single piston stroke in response to slip detector signals.

CONCLUSION

The ACE 3000 is a new locomotive for a new era. It incorporates major innovations in combustion, engine design, and locomotive control, each of which have been adequately demonstrated in other related applications. The innovative aspects of the design and its unique configuration distinguish it from previous locomotives insuring clean, efficient, reliable, and low maintenance operation that is entirely compatible with current railroad operating practice.

Economic aspects of locomotive operation have been discussed elsewhere, and present a picture that strongly favors conversion to coal, regardless of type of engine (2, 6). The ACE 3000 has been designed as a near term alternative which its developers hope to have available for railroads in the United States and elsewhere early in this decade.

REFERENCES

Association of American Railroads, "Operating Statistics of Class 1 Railroads, 1979," 1980; and Association of American Railroads, "Operating statistics of Class I Railroads, '1980," 1981.

Liddle, S.G., Task Manager, "Future Propulsion Systems for Railroad Locomotives," Jet Propulsion Laboratory project for U.S. Department of Energy, Contract NAS7-100, final report in preparation.

Stoffels, W., Lokomotivbau und Dampftechnik, Birkhaaser Verlag (Basel: 1976); see also, "Turbine Locomotives," in Locomotive Cyclopedia of American Practice. 15th ed., C.L. Coombes, e d., compiled for Association of American Railroads - Mechanical Division, Simmons Boardman (New York: 1956), pp. 435-444.

Norfolk & Western Railway, "Locomotive Performance Tests," 1952; C.E. Pond, personal communications, 1977.

Chapelon, A., La Locomotive a Vapeur, 2nd ed., Balliere et Fils (Paris: i952); Chapelon, A., "Modernizacion de Locomotoras," Pan American Railway Congress (1957).

"DOE/JPL Study: Coal is the Way to Go," Railway Age, July 13, 1981, p. 40.

Navitsky, G.J. and Gabrielli, F., "Boiler Water Treatment, Feedwater Treatment, and Chemical Cleaning of Drum-Type Utility Steam Generators," Combustion, (August, 1980) pp. 19-26; Badget, F.W., et al., "How to Care for Power Boilers," Power, Vol. 124 (December, 1980), pp. 33-40.

Porta, L.D., "Steam,. Locomotive Development in Argentina," Paper No. 721, Journal of the Institution of Locomotive Engineers (London; 1969), pp. 205-256; see also, "Improvements in Steam Traction in Argentina," The Railway Gazette, April. 4, 1969, pp. 271-273.

Return to The Ultimate Steam Page