|

|

- 1.

Builder

Mark Mogil's Comments

- 2.

Photos

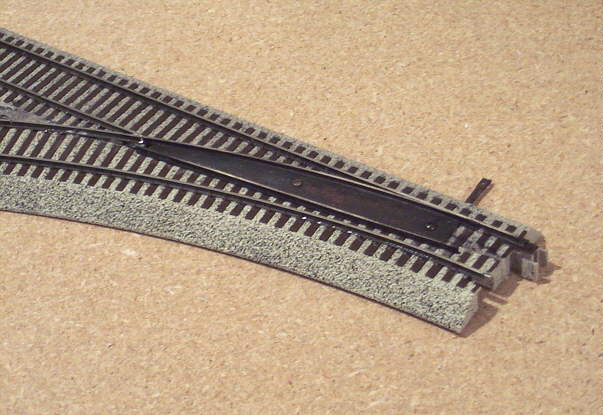

- SUMMARY: This

web page decribes some custom-made, closed-frog S-gauge

switches, built from S-Helper Service S-Trax track by

Mark Mogil, working with supervision from "the Gibbstown

wizard", Chick Viggianno of Chick's

Hobby Center

in Gibbstown, New Jersey.

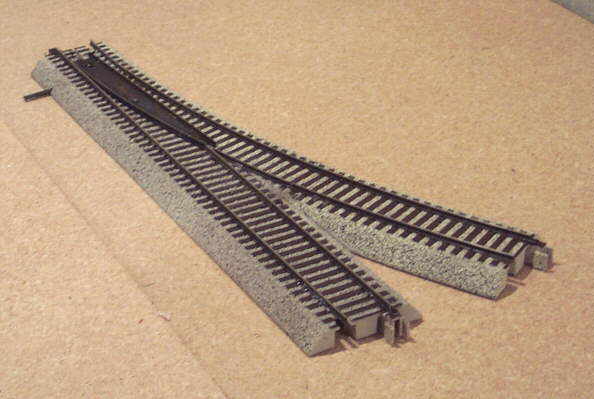

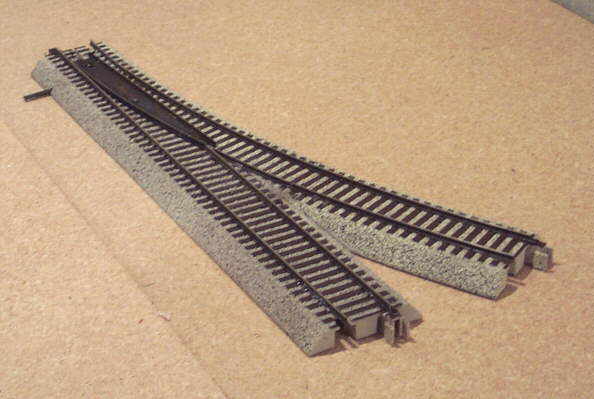

- Note that Mark has

done this by combining a piece of straight S-Trax with a

piece of curved S-Trax. In other words, he does not begin

with a switch. He begins with two pieces of plain track,

and "kitbashes" them into a switch.

- Please note that

Mark and Chick are NOT selling or marketing these

switches. They are making just a few for their own

use.

Currently (Aug 2000) there is one of them on display in

Chick's store you can inspect, if you're in the Gibbstown

area.

- Editorial

Comment--This is the switch that some of us S-Trax

fans wish that S-Helper would have built, so that

we who want to do public displays, instead of fighting

over whether the switches are going to be scale or

hi-rail, could use one style of closed-frog switch and

run anything.

1.

Builder Mark Mogil's

Comments

|

The following comments are

per the builder, Mark Mogil:

{(8/10/00)

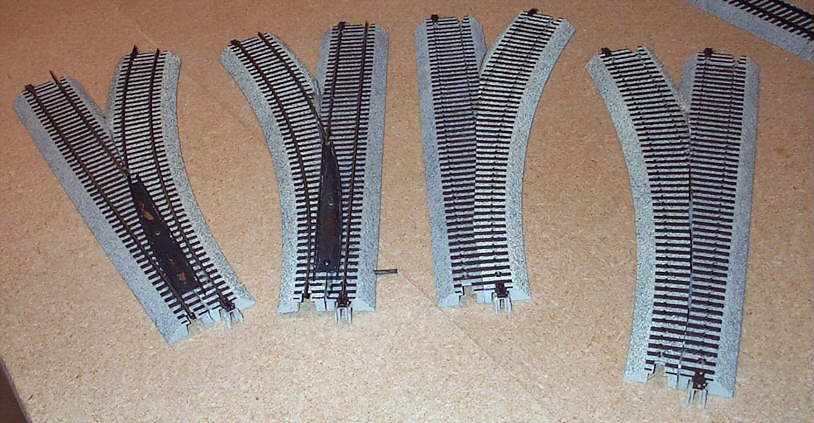

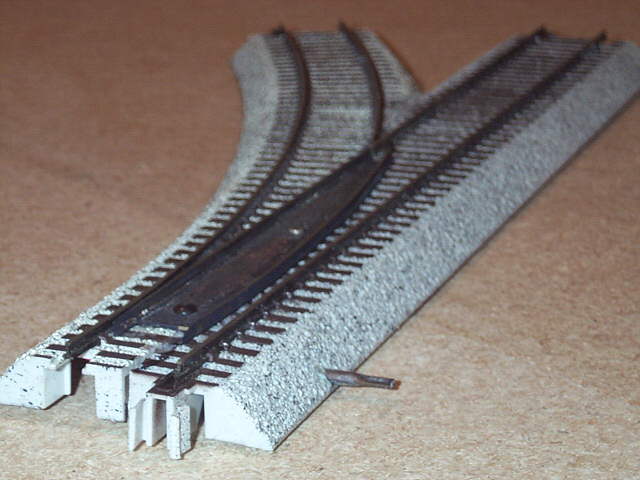

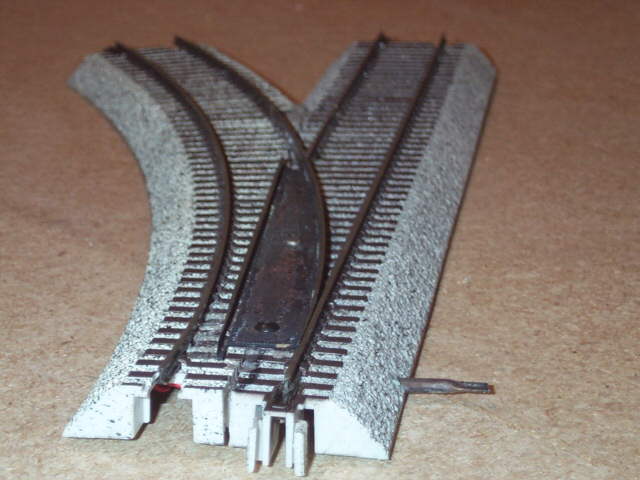

- As you can see, only

two of the turnouts have finished track work, and only

one has a throw mechanism. Counting the one you saw a

Chick's Hobby Center, there are only three closed frog,

S-Trax turnouts in the whole universe.

Worse yet, there are only two more presently in the

works.

- The good news is that

the finished turnout works! An American Models Pacific

4-6-2 with scale wheels ran through the turnout

flawlessly in both directions. But most importantly, it

was pulling two SHS box cars withthe stock hi-rail

wheels.

- This first batch of

turnouts took Chick and me about 20 hours.

Obviously, the most difficult task is fabricating the

moving track work. It requires cutting a brass plate, and

soldering rail on its edge. The soldering was the really

hard part, but after a considerable period of trial and

error, and error, Chick found a soldering technique that

worked pretty well.

- I would consider this

project to be a labor of love, as any hobby should

be.

- Please feel free to

use this idea, photos, etc., for the benefit of

S-Gaugers. However, since Chick and I spent quite a few

hours on this concept, please credit us if you distribute

these pictures.

Regards

Mark Mogil

Photo 1

Photo 2

Photo 3

Photo 4

Photo 5

Photo 6

Photo 7

Photo 8

This page modified 9/3/2006 by James

R. Ingram

. . Williamsport PA

|