|

Here are some of the tools and materials you will need

to build your own American Flyer 4-6-6-4 Challenger: Materials- 2 junker America Flyer Hudsons. Sheet metal, metal impregnated epoxy (JB weld), epoxy clay, lead, nylon skateboard rail, and satin black spray paint. Tools- Safety glasses, bench grinder, fine wire brush,

During construction, I didn't use exact measurements.

|

|

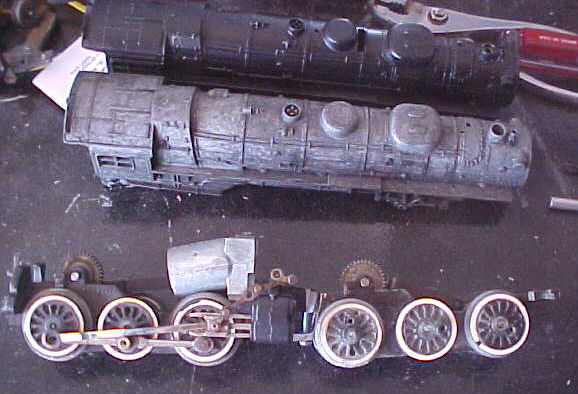

(Picture 1-1)

These are the victims, 2 American Flyer 322 Hudsons that were junked out. One is striped and the other is painted so one could tell them apart during construction. Disassemble all of the parts from the boiler shells and strip all of the handrails, cotter pins and piping. (Picture 2-1)

|

|

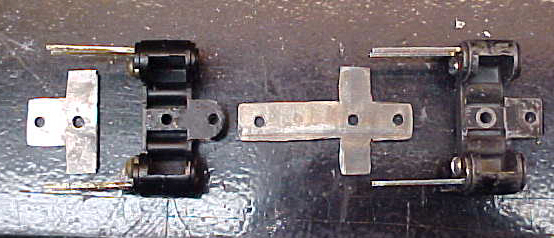

(Pictures 3-1 and 4-1)

These show the sheet metal brackets that need to be made to support the steam cylinders. |

|

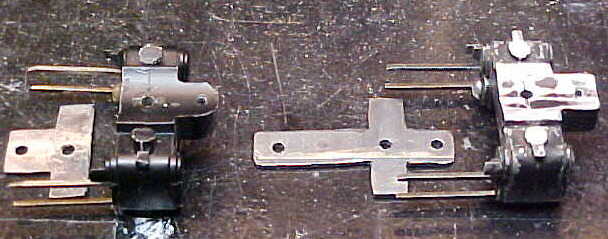

(Picture 4-1)

Note the extra modifications made to the front of the steam cylinder for the rear chassis (left). It needs to be rounded and then angled slightly downward. The only modification that needs to be made to the steam cylinder for the front chassis (right) is to grid the exhaust pipes smooth with the tops of the cylinders. Then grind the outside edges of the cradle down so they are even with the center/lowest point of the piece. This is so the bottom of the boiler shell will clear it when the engine goes around curves. Extra note: In (picture 4-1) the steam cylinder isn't ground down enough. |