Stelco's Railway

Steel Company of Canada

Yard Services Transportation Department

By Ray Hoadley

All photographs Bay City Railway

Historical Foundation unless otherwise credited.

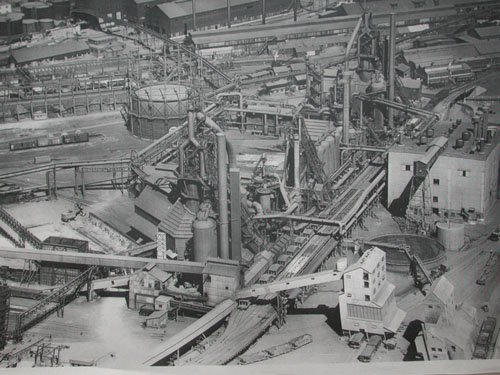

Stelco "D" Blast Furnace and Domestic Coke Screener

in the foreground. 1953. (click to enlarge)

In 1893, permission was granted by the municipal council of the City of

Hamilton Ontario to construction a blast furnace at Huckleberry Point

on Hamilton Harbour. The Hamilton Blast Furnace Company completed construction

in 1895 and began producing pig iron in the tiny blast furnace that summer.

The fledgling mill changed names to the Hamilton Steel and Iron Company,

reorganized as the Hamilton Iron & Steel Company before it joined

forces with several other small mills across Canada in 1910; The Canada

Screw Company, Canada Nut & Bolt Company, The Montreal Rolling Mills

Company and The Dominion Wire Manufacturing Company to become the largest

steel company in Canada, The Steel Company of Canada, more commonly known

as STELCO and June 30, 1980 re-named Stelco Inc.

#4 Dock (left to right) Blast Furnaces D, B, A and C.

1953 (click to enlarge)

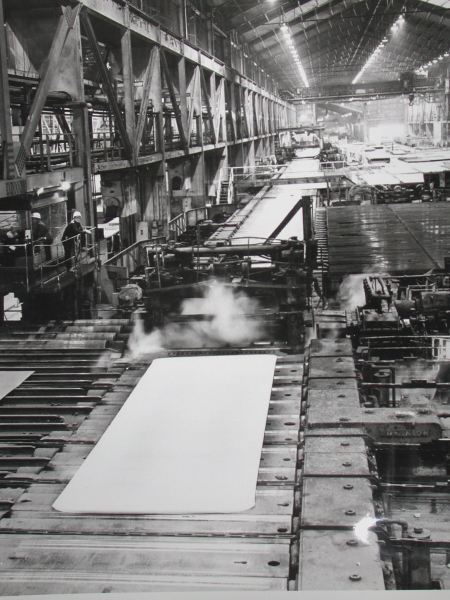

Plate mill

Locomotive Fleet

Locomotive

Gallery

The movement of pig iron and associated materials demanded that the infant

company set up an industrial intra-plant railway system. The first six

locomotives were simple 0-4-0T steam locomotives purchased from defunct

logging companies. As the workload increased over the years the locomotives

became increasingly larger, advancing eventually to 0-6-0 tender type

switch locomotives, many purchased from the Toronto Hamilton & Buffalo

Railway. The first brakemen hired by the new company were drifters (a.k.a.

boomers) off the railroads. Some only worked in the yard seasonally to

avoid the frigid weather on the road.

By 1948, there were 15 locomotives in yard service including steam and

the first diesels. These were 80 ton center cab General Electric switchers

assigned to roustabout duties because of their good tractive effort and

low upkeep. Soon this type of locomotive proved too light for the heavy

trains that were being marshalled and were eventually assigned to lighter

work, shunting scrap and ingot buggies.

The demand for heavier locomotives resulted in the purchase of a 1200

horsepower SW9 in 1951. During the next sixteen years, the Diesel Division

of General Motors built seven SW8 and sixteen SW900 locomotives. These

diesels solved the traction problem quickly and soon the little saddle

tank steamers found their way to the scrap lines. By the end of 1967 the

company had a total of 29 diesels in yard service.

Of special interest was Stelco #40, previously TH&B #40. It arrived

in operating condition in September 1959 and was retained for ten years.

Initially used as a plant switcher, it was soon displaced by the new diesel

fleet. However, #40 escaped the scrappers' torch, when it was used as

a portable boiler during the rebuilding at the Plate Mill and later the

12-10 Mill. Roundhouse foreman, Gord Douglas, supervised a complete overhaul

of the locomotive before it was donated to the National Museum of Science

& Technology in Ottawa in June 1969. It operated there on museum property

providing short train rides until it was once again retired. Stelco #40,

ex TH&B #40, nee TH&B #42 now resides in Lindsay Ontario.

Rail Operations

Left photo: Old eastside yard for inbound and outbound road cars. There

was a newer eastside yard built after this photograph. Right: Westside

yard for inbound and outbound road cars. Note: The old black building

is the Spike Mill where rail spikes were made. Both photos, circa 1948.

Canadian Science and Technology Museum/CN Collection

The Steel Company of Canada operated eleven different facilities in Hamilton,

all requiring rail service. They included Hilton Works, Reinforcing, Parkdale

Works, #2 Rod Mill, Frost Works, Laidlaw Storage, Canada Works East &

West, Ontario Works, West End Storage and Canadian Drawn Works.

By far the largest operation, at six million annual ingot tons in 1972,

was the 1110 acre Hilton Works. Operating as an integrated steel mill,

which could produce new steel from raw materials required a vast quantity

of iron ore, dolomite, limestone and scrap steel. Much of this was delivered

in railway cars, although iron ore and coal also arrived by lake freighter.

The Stelco Railroad, operated by the Yard Services Transportation Department,

employed 600 people in operating and non-operating jobs. Five track gangs

maintained the 72 miles of track, including over 700 switches and repaired

the high priority derailment damage. The Diesel Shop could conduct daily

maintenance on up to four locomotives at a time or do a complete overhaul

on any locomotive in the fleet.

Co-ordination of rail movements was the responsibility of a shift yardmaster,

who was in contact with the TH&B and CNR yardmasters, and four assistant

shift yardmasters. The twenty-seven, four man crews operated around the

clock, seven days a week. Many were employed to move the 1500 pieces of

steel mill rolling stock throughout the plant, most of it not equipped

with air or mechanical brakes, relying strictly on the skill of the engineer

to control the speed of the train. Trainline reservoir air was bled from

inbound railroad cars before they were weighed at #3 or #5 track scales.

Feeding a Hungry Steelmaking Facility

Producing new steel at an integrated steel mill required millions of

tons of scrap steel, which was mixed with the molten iron from the blast

furnaces. During the 1950's, Stelco purchased scrap from as many sources

as it could. Aging lake freighters were tied up for the last time at #1

Ore Dock. The boat salvage crew slowly winched the hulls out of the water

as they torch cut the superstructure into pieces small enough to charge

into the open hearth.

Click to enlarge

The rolling stock was purchased second hand, often as scrap from the mainline

railroads. Once inside the plant, the Car Repair Shop removed the brake

equipment, renumbered it and it remained in service for many more years

before it was scrapped. New rolling stock such as ore jennies, three bay

hoppers, gondolas and billet flat cars began replacing the aging fleet

during the 1970s. In fact, the Car Repair began fabricating heavy duty

gondolas based on the weaknesses of the original cars.

Steam locomotives also provided dense steel scrap from their cast frames

and running gear. Workhorses of the New York Central,

Chesapeake & Ohio as well as local Canadian

locomotives did not escape the scrapper's torch. Most of TH&B's steam

locomotive fleet was purchased by Stelco, however not all of them were

immediately scrapped. Many of the switchers were re-lettered and remained

in active service at Stelco for several years.

Number 2 Bloom Mill with three Hi-Riser cars; in the background

is building of #2 Conditioning Dept.

Over one hundred and twenty-five tender frames equipped with six wheel

Commonwealth or Buckeye trucks were saved for moving red hot steel slabs

within the plant. These cars were ideal for this type of service. Their

cast steel and rivet construction could withstand the high temperatures

of 150 tons of steel, when a welded construction car would have soon collapsed.

They were refitted at the Car Repair with a coupler at each end and heavy

steel plate risers to raise the hot slabs above the floor of the car,

which was covered with six inches of slag to dissipate the heat. Many

of these cars remained in service until 2001, nearly fifty years later.

These near-indestructable Hi-Riser cars were rebuilt in

the 1960's from steam locomotive tenders. Ray Hoadley

Reindeer car 205, (one of about 8 such cars rebuilt c.1960's

from Hi-Riser cars to carry hot billets),

shown at the 10-9 Mill's billet yard.

Several "Hi-Riser" cars for the #2 Conditioning

Department. Ray Hoadley

Switching Hilton Works - Circa 1972

In 1972, at the height of operations, the railroad switched five blast

furnaces, seven coke batteries, two steelmaking open hearths with eleven

furnaces, a Basic Oxygen Furnace with three vessels, two ingot stripper

buildings, a Universal Slab Mill, 148" Plate Mill, 56" Hot Strip

Mill, two bloom & billet mills and numerous billet and flat-rolled

finishing mills.

The following describes the typical daily interchange with the Toronto

Hamilton & Buffalo Railway.

0100-0200 TH&B geeps placed iron ore pellets loaded in TH&B or

CP 3 bay offset hoppers from the Hilton iron ore mine as well as cars

of Buffalo coke loaded in NYC hoppers to track 35 in the Ore Yard near

Industrial Drive. The light geeps then pulled the outbound cars from track

31. This usually contained the empty hoppers from the blast furnaces and

any miscellaneous cars from the ironmaking area of the plant such as shipments

of pea, nut or egg coke from the Domestic Screener and empty coke hoppers

from the blast furnace. These cars were pulled to nearby Fisher Yard.

0200-0300 The geeps then returned with the miscellaneous inbound cars

for the east side of the plant and placed them to track 565. This could

include PRR or NYC box cars of fire brick for a variety of blast furnaces,

open hearth furnaces or reheat furnaces in the mills. Zinc ingots, loaded

in Norfolk & Western box cars would be unloaded in the galvanize lines.

Manganese, a steelmaking additive arrived in TH&B 40' box cars with

8' doors. These cars were characterized by the dents in the roof caused

by the manganese being deflected off the roof during loading. TH&B

48' gondolas in the 2200 series shuttled between the local scrap dealers

and the open hearths. Finally, empty rolling stock was placed for steel

shipments. These included CP 65' narrow gondolas to load 60' lengths of

reinforcing rod and 52' gondolas for angle stock, bars, billets and fence

post. TH&B or CP 70 and 100 ton flat cars were placed for plate shipments.

The crew then pulled track 567, the billet shipments for #2 Rod Mill.

These were generally TH&B 2300 series "con-cast" cars equipped

with steel racks and loose stone floors. They were loaded with hot billets

from #16 open hearth caster, #3 Bloom & Billet Mill or #3 Conditioning.

1400-1500 Using a TH&B switcher, the crew placed the con-cast gondola

empties to track 565 after making the reverse at #2 Rod Mill about noon.

The locomotive then pulled the outbound cars from track 563. This could

include plate in either gondolas or loaded on flat cars for Welland Tube

or any other customer. Tin or galvanize coated steel coils were shipped

in regular box cars in warmer weather or heated box cars in the winter

to prevent oxidization. The balance could include empty brick box cars,

empty scrap gondolas or rod and bar shipments.

1900-2000 Again using a switcher, the TH&B placed miscellaneous cars

to track 565 or track 35 in the Ore Yard. The light engine would then

pull the con-cast loads for #2 Rod Mill from track 567.

If additional Hilton ore or more empty gondolas or flat cars were required

to meet production needs, the railway would be asked at any time to make

a special delivery. It was not uncommon for the TH&B to move over

a hundred cars a day for Hilton Works. During this same twenty-four hour

period, Canadian National also provided similar service.

Today

Stelco Hilton Works, recently renamed Stelco Hamilton, still remains

one of the largest integrated steel mills in Canada, producing 2.5 million

tons of steel. Many of the production facilities, which relied on rail

transportation have been demolished in favour of new steelmaking technology

so the railway no longer plays as important a role. Rubber tire equipment

such as multi-wheel 200 ton capacity Paling Transporters move billets,

coils and scrap, while Kress carriers transport hot slabs and blooms from

the caster to the hot strip mill and bloom mill.

The railroad has been reduced to less than twenty-five employees operating

three roustabout locomotives while two other locomotives are dedicated

to the remaining blast furnace to switch hot metal cars out of from under

the casthouse floor. The fleet has been reduced to nine locomotives. The

other twenty diesels have been transferred to another Stelco facility,

sold or cut up for scrap.

A collection of Stelco artefacts, which had never been on public display

were donated to the Bay City Railway Historical Foundation in 1999. They

are now exhibited at the H.O. Model Engineers Society Inc. in Stoney Creek.

Simplified Stelco Hilton Works Railroad Roster

5 American Derricks - 80 ton capacity

6 0-4-0 T

1 0-4-0

2 0-6-0T

15 0-6-0

4 Electrics converted to gas electrics

5 GE 80 ton center cabs

1 GMDD SW9

7 GMDD SW8

16 GMDD SW900

|