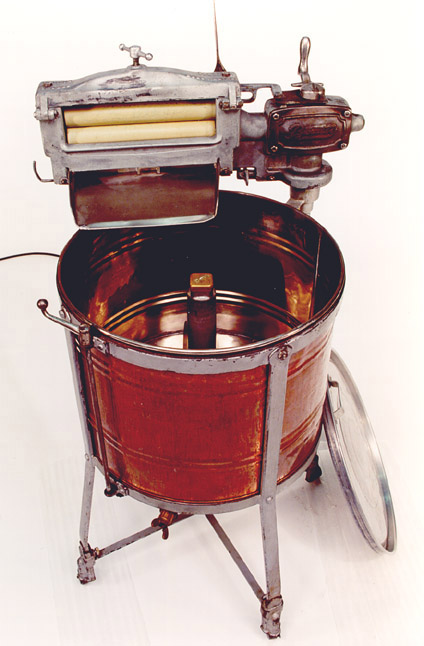

Beatty Bros. Ltd

1927

electric agitator washer

Beatty family of Fergus, Ontario in front of Beatty

Jubilee Train at CPR Fergus station, 1934; photographer unknown.

Wellington County Museum and Archives

"Village Industry Sells to Whole World,"

Financial Post, July 14,

1934, p.1.

Beatty Brothers of Fergus, Celebrates Sixtieth Anniversary --Founded

by Two Brothers and Is Now Run by Two Brothers

by Gordon L. Smith

--------------------------------------------------------------------------------

Sixty years ago, two brothers, George and Matthew Beatty by name, opened a small

farm implement factory in Fergus, Ontario. At this early period the whole of the

settled portion of Canada was dotted with such village industries. The firm they

founded has just celebrated its diamond jubilee. It is still in Fergus. It is

now an international organization. It has expert outlets in Great Britain and

New Zealand. It sells its wares in almost every country in the world. But it continues

to function largely along the lines laid down by the founders.

In short,

Beatty Bros. is still a village industry, but it is one that has grown to vast

proportions, without identity-losing mergers, and without abandoning the place

of its birth. It is still run by two Beatty brothers - W.G., the president, and

M.J., the secretary - and they are songs of the original George.

Contact

With Public

It has retained, since its inception in 1874, intimate contact

with its customers and its employees. Since it sold stock to the public it has

retained intimate contact with investors.

The big modern factory is located

on farm land with an active company farm at the rear. The company-financed houses

of the employees stand in the foreground. Practically all of the officials of

the concern have risen gradually to their present responsible positions through

the factory and the office. There have been no strikes, nor prolonged periods

of unemployment.

Until a very short time ago, there was no outside capital

involved. Finally, when expansion of business necessitated the inclusion of more

money, the people contributing it were considered a first obligation on the firm.

Small Town Industry

One by one most of Canada's old village industries

were forced to give up, or moved to the large cities and merged with others. But

Beatty Bros. continued the traditional personal policy of using its own inventions

- its own mechanical brains in other words, coupling with this the modern policy

of mass production at low cost. By adding or switching to new lines it managed

to retain its leading position. Products were selected to meet the peculiar circumstances

governing the factory and its location. When the day of hand-made, heavy farm

implements passed and cheaper and better steel allowed mass production and distribution

of plows, harrows and binders from centrally located plants, then Beatty Bros.

abandoned farm implements. The company entered a field where there was less competition

but scope for more original development, and one, therefore which suited better

a small town which was long on skilled labour but had no floating unskilled supply

to be turned on and off as a tap when orders flowed in or ceased.

"We

are responsible for our employees," stated W.G. Beatty, president of the

firm. "Fergus is a small place and a man cannot go from one job to another

as he might in Toronto or elsewhere. When we take on a man we feel that he is

part of the business and that his family too is vitally concerned. As a result

we hire carefully and sparingly, but we try to provide year round work."

New Showing Gains

This was the underlying reason for adding new lines

to the company's output, lines which would keep the factories and salesmen going

in the off season. Of these lines, more will be said later.

That this selection

of new products was shrewd is well illustrated by the steady growth of the company,

and the annual increase of the pay roll.

With the exception of a brief period

during the depths of the last depression, expansion has been continuous. For a

little while, married men were put on a four-day week and single men on three

days, but that has passed; and in some lines overtime is now necessary. Every

month for over a year sales have shown consistent gains.

Founder of Firm

The founder of the business was the late George Beatty, born in 1845 on a

farm in Albion Township, in the north part of Peel County. His parents were Irish.

The present Beatty brothers are still satisfied with the nationality and have

never attempted to adopt the Scottish spelling of the name. George Beatty, I was

told by the sons, W.G. and M.J., the present Beatty brothers, was a big man well

over six feet. He had plenty of strength and gloried in it. At 18 he left the

farm, apprenticed himself to Haggert Bros. of Brampton, who had quite an important

farm implement business in the early days and specialized in threshers. George

Beatty was not at all satisfied with the primitive implements of the time and

soon was helping to turn out better ones. His apprenticeship over, he and his

brother Matthew moved to a new field, Fergus. There with four or five helpers

they were soon turning out a complete line of farm implements. George Beatty was

the inventor, while Matthew largely took charge of the selling. Matthew Beatty

died some eleven years after the company was founded and George Beatty carried

on alone.

Inventive Genius

Whenever George Beatty took on a new line,

he invented something better and different and patented it. The same methods are

being carried on by the present generation. W.G. Beatty, the president, who looks

after the production end of the business, has 300 patented inventions to his credit.

M.J. is the salesman.

The first business was confined to territory within

a few miles. It was strictly a village industry, serving the needs of the adjacent

county.

Not very many years after getting started, George Beatty took his

reaper to the Toronto Exhibition. There in competition with the largest firms

in the country he carried off the gold medal. The machine was taken out into a

standing field of grain and given a practical test. "After that," M.

J. Beatty told me, "there were no more competitive classes for machinery

at the Toronto Exhibition."

Fame Noised Abroad

This advertising

proved a stepping stone for Beatty Bros. Orders came in from territory far beyond

Fergus. Farmers wanted to buy the gold medal reapers and other machines from the

same factory.

Until 1900 Beatty Bros. continued to turn out farm implements,

each year adding some new device, some mechanical improvement to ease the burden

of sowing, cultivating or harvesting the products of the farm but at the same

time simplifying the machine, cutting down the number of moving parts, making

it lighter and turning out the completed product at less cost. Even before Mr.

Ford had adopted his well-known automobile production methods, the Beattys were

applying the same methods of simplicity and mass production to farm implements.

But competition grew strong and the larger plants were adopting the same inventions

which gave the Fergus firm its original leadership.

Buy Other Industries

In 1900 the manufacture of farm implements ceased, and the firm started manufacturing

barn equipment, a new line which allowed more scope for inventive genius.

In the meantime the two present Beatty brothers were getting their training. They

lived on a small farm and learned by experience the farmers' problems. Holidays

were spent in the factory. In 1901 both brothers graduated from Toronto University

and went into business with their father. The growth of Beatty Bros. has been

accelerated by buying other industries. The biggest step of this kind was taken

in 1912 when the business of Wortman and Ward, pump and washing machine manufacturers

of London, Ontario was purchased for $200,000.

This added new lines which

could be turned out when barn equipment was not wanted. More important still,

it opened up new territory, giving the company the whole of Canada, as Wortman

and Ward had connections in the West and the Maritimes. Agencies were continued

and wherever possible the products were sold through the local retailers.

Growing With Electricity

The extension of hydro-electric power throughout

the country, which started just before the war, helped matters substantially.

Farmers were able to utilize electric washing machines, power driven pumps and

other devices of the Fergus factory. Lines were added until about 35 different

products, including all sorts of pumps, washers, ironers, windmills, barn and

stable equipment, ladders, baskets, and similar things were being manufactured.

Growth was rapid. The suggestion of moving to a larger place was discussed.

There were advantages in a more central location. Both the main railways crossed

the company's Fergus plant, but there was the question of a more abundant supply

of labor, cheaper power and fuel.

Advantages of Small Town

"We

would have been money ahead to have left Fergus" W.G. Beatty remarked, "and

in some respects we might be better in Hamilton or Toronto today, but we like

Fergus. There are certain advantages that a small town has to offer. We feel responsible

for the continual employment of our employees. In a small place like this there

is a definite personal connection with every man in the plant. Our staff has always

been loyal, rendering the highest type of service."

Concrete advantages

there are, too. Mr. Beatty told me that his modern factory had cost less to build

than it would be possible to rent space for a year in some of the large centres.

The men are working a ten-hour day at present but they are so close to their homes

that only a handful bring their lunch. While the average workman in Toronto or

Montreal must spend at least an hour on his way to and from work, within a few

minutes of the six o'clock whistle the Beatty employees are in their gardens,

at play or at the supper table.

Houses for Employees

A few years ago

the firm secured most of the vacant land in and about the town and this was sold

to employees at cost. A good sized lot cost less than $75. The company helps the

man to finance the building of the house. Here again the service is supplied at

cost. these company houses must not be confused with the long dismal row of cottages

that are part of the company towns in other parts of the world. The houses are

not all alike, either in size, material, appearance or cost. The lots are large

and the buildings of a substantial middle class nature. There are parks and there

is a magnificent community swimming pool, with special diving boards. There are

ample facilities for sports, from horseshoes and tennis to golf, in the village

of Fergus.

The woodworking division is housed in a part of the original Beatty

Bros. plant. The walls are stone, pleasingly weathered and covered with ivy and

the new plant is also largely constructed of stone. But inside all is modern bustle,

with the largest mass production machines. One noticeable feature, however, is

orderliness. There are no loose piles of raw material and no dangerous clutters

of waste.

Room To Expand

At the back of the well-lighted factory is

a long temporary wooden partition with windows looking into a field of wheat.

On either side and extending into the wheat field are two stone walls. "When

we want to extend a line" explained Mr. Beatty, "We simply take down

the partition and go farther out. There is plenty of room there."

I

was told that over $70,000 worth of new machinery has been installed this year

alone. "We can't afford to get behind." W.G. Beatty said on our tour

of the plant. "We have always been in favor of new machinery. We are continually

in touch with the large plants across the boundary for tips along this line.

"The introduction of such labor saving machinery, however, has never resulted

in any men losing their jobs. When we install something that will cut labor costs

we have always been able to step up production and sales. The old labor is retained.

Usually the change, because of the increased sales following the lowering of costs

and prices has actually resulted in more men being taken on."

Aid From

Other Countries

Beatty Bros., at no time, have gone into the business of

making parts for other companies. During the war the company did not even make

munitions or other man-killing equipment, but generous tribute was paid to the

automobile industry for the help given in the house and barn equipment field.

I was shown at least half a dozen different processes which trace to the advent

of the automobile. There is a new machine which turns out worm gears for the Beatty

washer at the rate of one every 30 seconds. These first were used in the starting

device of the motor car and had not some big field like this opened there would

have been no worm-making machine which "does it better and faster than we

did it before."

Using Modern Methods

The painting of the washers,

ironers, pumps and other things now takes place at the end of the assembly line,

whereas before the invention of fast-drying enamels, a trip had to be made to

a special and expensive paint shop where the finish took a day instead of moments

to dry and where the air had to be treated continually to keep down the dust.

Steel plates, that can be pressed into washer bottoms in one-secondlong operation,

also first came from the auto factory, as well as the new anti-rust treatment

of metal covers and other parts. A huge, new machine now being set up to manufacture

garage and barn door track and rails for litter carriers, was first designed to

make the window frame and sash of the modern skyscraper.

"More and more

are we benefitting from other industries," said Mr. Beatty "and more

and more are farmers going to come to town for such equipment. I look for the

time when the complete barn will be built in such factories as ours. The average

barn today is a tinder box, especially when filled with hay and straw. Eventually

one-story steel affairs will replace these, with the livestock in low, steel covered

concrete and metal structures, practically fireproof and the feed compressed and

stored in fireproof silos or big all metal barns.

Testing Laboratory

The Beatty plant is not all factory. Right behind the general offices, is a laboratory

where the continual flow of inventions must stand the practical test before they

are passed on to the regular plant and the customer. Usually a couple of hundred

units are made here to make sure that the gigs, tools, templates and patterns

are right and will work properly.

At present there are about 2,000 people

on the payroll of whom 500 are employed in Fergus alone and others at various

plants of the company and sales offices throughout the Dominion and abroad. The

business is divided roughly between barn equipment and household appliances used

in both town and country. Since the war, an export trade amounting to about 20

per cent of the total business has been developed in Great Britain, New Zealand

and elsewhere. This development was interesting and closely resembled the start

into the national field following the winning of the gold medal by the Beatty

reaper.

Export Beginning

M.J. Beatty, who has charge of the sales end

of the business told me "The first big start in the export field was made

in march 1919 when we were induced to make up a shipment for the Lyons Exposition

in France. The government and the Canadian Pacific Railway co-operated. The C.P.R.

overcame tremendous difficulties in getting some sixty Canadian exhibits over

to Lyons in record time. We sold $50,000 worth of products during the fair and

had a nice business in France for three years. During that time we established

connections in Great Britain and have been going ahead there ever since."

Other export fields were investigated. "We wanted some place where we

could sell both city and country and so hit upon New Zealand and where most of

the farms have electric power. We have stores in the four main New Zealand cities

and have been doing a nice business there. Exports go to nearly every country

in the world but New Zealand and Great Britain are the principal outlets."

Keeping Down Inventories

Special attention is paid to the sales force

and every effort is made to make salesmen and retailers feel that the firm is

behind them. Following the old farm implement idea, agents are appointed in the

various districts, or if none can be secured a store is opened. There is no attempt

to push sales too hard and never is the agent loaded with a lot of goods in advance.

"We were very thankful for such a policy when we entered the depression,"

stated Mr. Beatty, "because it resulted in neither the agent nor the company

having an excessive inventory. It helped again when things started picking up

last summer, as we did not have to clear out a lot of old goods before we could

commence on the new and constantly improving lines."

The company sells

appliances and certain equipment on time but always handles its own financing,

never having discounted any paper.

By 1929, having become the largest manufacturers

of washing machines and ironers in Canada, turning out more than all other Canadian

competitors combined and the principal makers of barn equipment, and household

power and hand pumps used in the country, the company found it necessary to go

outside for capital to handle the growing volume of business. Both preferred and

common stocks were sold. On both classes of the former dividends have been paid

regularly.

A mild sensation was caused in financial circles in 1932 when

dividends were continued on the Class A common, which was largely held by the

public, a year after dividends were discontinued on Class B, largely held by the

original owners. The Beatty brothers were under no obligations to favor the outside

investors but they did. This reversal of the usual practice might have seemed

strange to the average financial man. But it was in keeping with the Beatty village

industry tradition of invariably putting the interest of the public in the foreground.

____________________________

____________________________

- Some

additional historical information is found on the web site of the Heritage Committee

for the Township of Centre Wellington, from which this brief sketch was taken

in October 2001. See also the section on the "Origin of Brock Avenue".

At the time of this writing, the url for the site is: http://www.twp.cwellington.on.ca/Heritage/District/historic.htm

The Beatty Brothers Factory

George Beatty, a machinist,

and his brother Matthew, a farmer, came to Fergus in 1874 and, in that year, started

a business for the manufacture of farm equipment. Their first factory was

on Saint Andrew Street West, in the

building now known as the Old Temperance

Hall, which still exists. An old woodcut drawing of this building

shows that

there were trees in Saint Andrew Street, in those days. George Beatty was also

an inventor who

designed most of the firm's products. His reaper received

the Gold Medal at the Toronto Exhibition in

competition with such prominent

makers as Massey, McCormack, and Harris.

In 1879, the brothers built a new

water powered factory on the River Grand. This building still exists, and now

houses the Fergus Market. In 1901, George Beatty's sons, William and Miltion,

joined the business. The firm

prospered and, in 1911, a new, steam-driven

plant was built on Hill Street consisting of 12,000 square feet of

office

space, and 28,750 square feet of factory floor and boiler room. Between 1920 and

1929, more than a

quarter of a million square feet of floor space were added

to the Fergus plants.

-Many of the company records are located at the William

Ready Division of Archives and Research Collections at McMaster University Library

in Hamilton. A description of the archival records is found at the following url

as of 2001: http://www.mcmaster.ca/library/readydocs/findaids/fonds/b/beatty.htm.

- For an image of the Beatty "agitator" (washing machine)

see the Canada

Science and Technology Museum web site.

Additional information and

images relating to Beatty's "invention" of the washing machine are found

at site -

"The

Great Idea Finder".

Business Library Staff

University of Western Ontario

More recent history.

1969 Beatty Brothers was amalgamated with General Steel

Wares becoming GSW Limited.

2006 GSW was acquired by A.O.Smith which began making

water heaters in 1936 and became the world's largest.

April 2013 A.O.Smith Corporation announces closure of

500,000 square foot plant at 599 Hill Street West in Fergus by the end

of June with loss of some 350 jobs. Production of water heaters (the

only remaining product) for North America will be transferred elsewhere.

Various office functions to remain in Fergus with some 125 jobs. Marketing

of water heaters to continue in Canada under A.O.Smith, GSW and John

Wood brands.