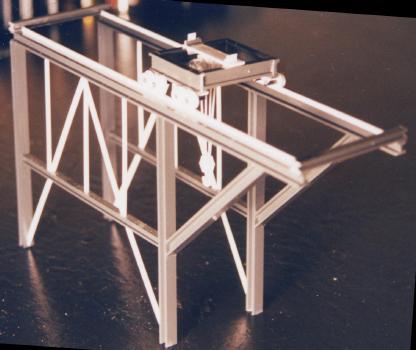

This section discusses the scratch building of the maintenance crane support frame, located on the bell platform under the maze of uptake piping.

The materials I used are Plastruct 'H' beams and Evergreen strip styrene. With a Nortwest Shortline Chopper and a small miter box, the pieces can be cut very easily. I have opted to NOT include much dimensional data, since the primary goal is to have a frame that can be placed in the center of a fully-assembled uptake piping tower. However, I did include measurements of the vertical supports and the top horizontal beams as a starting reference. The link below shows a diagram of the unassembled parts laid out.

Unassembled Pieces of Crane Frame

For the diagonal braces, I cut Evergreen ® strip styrene at 30-degree and 60-degree angles as shown, then overlapped the opposing pieces. [Since this was a "rush" job I did not use junction plates, though I now realize that would have been the correct approach. Hopefully few people will notice! :)] Click here to see side and end views of the assembled frame.

The final illustration shows how to position the frame beneath the uptake piping tower. I designed my furnace this way in order to be able to assemble/disassemble the plant for transportation and display either at conventions or on my layout - having the wide clearances makes it much easier to insert the frame onto the partially-assembled model.

Since I am running short of time, I will not be describing how I built the crane trolley (even though it is visible in the top photo). This series of documents, as I mentioned at the beginning, aims to show how to build the large items.

Dean Freytag and Jeff Borne have both written excellent instructions for super-detailing a Walthers blast furnace, I'll let them show you how to handle that part. C-ya in another week or two! -KJL 05/22/02