| Step 1) Starting with

disassembly, place the model on your workbench, desk or table to access

the top of the loco and the end of the tender. First remove the screw at the rear end of the tender

and place where it can be found for reassembly in the original hole it

came from. Pick up on the rear of the tender shell about a half inch

while holding the rear truck then

slide the shell forward about a quarter inch. the metal tab on the front

of the frame should disengage with the shell. place the shell out of the

workspace to protect it. |

|

| Step 2) Remove the screw at

the top of the cab and place it where it can be located for the return

to the same hole |

|

| Step 3) Remove the smokestack

insert. Use a regular screwdriver capable of fitting into the slots cut

in the top of the smokestack and turn counterclockwise like removing a normal

screw. The Franklin unit originally had a brass insert although it could

have been replaced with a plastic one at some point. Same rules apply. |

|

| Step 4) Remove the side-rods

from the drivers using an appropriate method. Pliers can work for

removing the fasteners but the

odds are great of scratching the screws and the side rod. A socket type

wrench is best for this one. Remove the drive rod from the wheel post

and slide the driver with the steam chest rod out of the frame and place

it somewhere out of your workspace. Repeat for the other side. Remember

which rod came from left and right. They may be bent individually for

clearances or you may have to straighten them for necessary clearance. |

|

| Step 5) Remove the two screws under

the front trucks that hold the chassis in the shell. Place them in a

location to remember where they came from |

|

| Step 6) Using the contact cleaner

OUTSIDE or in a very well ventilated area, clean the areas of the trucks

where the axles enter the side-frames and where the pickup strips

contact the axles. It appears to be ok to clean the wheels as well. I

have not noticed any degradation of material using the fast drying

solution. Clean both trucks in the same manner. |

|

| Step 7) Next clean the moving portion

of the e-unit. Try to stay away from the coil when spraying the oils

off. Generally this is clean from debris, but sometimes people put oil

on the mechanism to aid in its function, but the results are short lived

and the unit gets sticky refusing to change direction without

assistance. Always keep this unit clan and dry. It needs no oil. |

|

| Step 8) Spray clean the front journal

and worm drive of the armature to release old oils, fines, and tar

buildup from previous years of use. |

|

| Step 9) Finally, clean the rear

journal and commentator. As with the e-unit, try to stay away from the

windings. The wires are coated with a shellac and may be susceptible to

different kinds of contact cleaner. Better safe than sorry. |

|

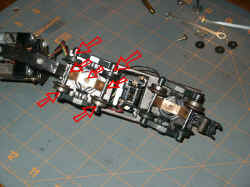

| Step 10) In the case of this

locomotive, the major reason for the hesitation and requirement for

tapping to get it going was due to the spring pickups loose on the

rivets. Hold the truck with one hand and swivel the pick-up from side to

side to check tightness of rivet. If it moves easily, then the current

can not make it through to the wire soldered to the other end. Using a

flat punch or a rivet tool, peen the flange over a little tighter. Remember

you are working on a delicate electrical unit, not constructing a

skyscraper, so tap gently and check for snug movement many times. |

|

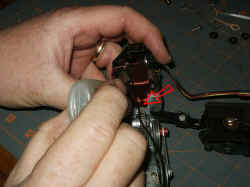

| Step 11) Next lets make sure the

contact is made between the pick up strip and the axle. When the unit is

upside down touch the wheel and push down gently. the strip should be

showing pressure on the axle by raising the axle in the side-frames. To

regain the tension, hold the end of the strip with one finger while

pushing lightly on the spring about 3/8 of an inch from where it bend

up. Push a little and check a lot. It is right when the axle picks

itself up from the bottom of the holes in the side-frame. Repeat for

remaining three strip ends and axles. |

|

| Step 12) Lets talk Oil. Any oil on the

motor that is extra will end up inside the engine shell or on the track

and wheels of all your moving stock and engines and that is guaranteed. Oil the front armature shaft bushing. Use oil

that is approved for plastics. It is a synthetic blend that will not attack the

shell. Place a couple drops on the shaft between the thrust washers and

the chassis. The oil- lite bushing will absorb some oil due to its

porosity and this will maintain lubrication for many hours. No more than

3-4 drops is needed for performance. |

|

| Step 13) Lubricate the brush end of the

armature. 2 drops is generally sufficient. Extra oil on this end will

cause brushes and commentator to get gummy and carbon up causing issues

so keep it lean. |

|

| Step 14) Lubricate the gear pin and

bolt for the smoke unit arm. A couple of drops is all that is necessary.

Do not oil the teeth of the gear or the lithium grease will not stick.

It generally is not necessary to oil the other end of the drive rod but

it does not hurt anything. extra oil in the chuff chamber where the

piston runs will lubricate the sides and reduce the volume of the

chuffing sound. |

|

| Step 15) A lubricant that I found that

works very well for contact on the pick ups is Anti-Seize or sometimes

called Never-Seize. It is used in the automotive industry to for

applications to threads and pins that you wish to remove at a later

time. Anti-Seize is made of Copper Powder, Aluminum Powder, Zinc Oxide,

and Graphite. These components are all conductors of electricity and

work very well on the pick ups to ensure contact and prevent oils and

debris from becoming an insulator. Using a tooth pick place a little on

the axle near the copper strip and rotate the wheel set. |

|

| Step 16) White lithium grease or Gear

lube at a hobby store is the lubricant of choice for the worm and drive

gears. the worm distribute the lubricant during operation between the

gears so you only need to put some on the top of the chuff drive gear.

spread it out with a tooth pick after adding. |

|

| Step 17) Reassembly is next. The

Franklin may or may not have rubber washers that insulate the sound

between the locomotive shell and the chassis. If yours does use a small

drop of general purpose adhesive on the back side of the washer and

place it over the hole that it covers. The deformation of the washer

should reflect which hole it came from and the adhesive will keep it in

place while you assemble the chassis to the shell. Next drop the chassis

into the shell lined up to the holes. |

|

| Step 18) Reinstall the screws that hold

the chassis front in place. Do this with extreme gentleness. This is

done by feel and generally is the primary cause in broken screw posts on

loco shells. When the plastic gets old it gets brittle. The screw

threads MUST find the original threads in the plastic boss made by it

from original assembly. Drop the screw into the hole and with a small

screwdriver turn gently clockwise. If resistance occurs, do not force

it. Turn it counterclockwise until you can feel it drop down a little

and try again. Make sure screw is straight. Make only snug. |

|

| Step 19) Install the screw in the cab

following the same procedure as the chassis. forcing will cross thread

the steel bracket and the screw will never tighten up again. |

|

| Step 20) Install the brass insert in

the smokestack using a screwdriver that captures both sides of the slot.

too small will break the slot. Make sure it is straight and it follows

the same procedure as the threads above. The insert screws into a fiber

plate which can be cross threaded easily as well. General rule of thumb

is to feel for resistance ant back it up until it drops a little, then

start again. This procedure uses the same feel as picking robin eggs

from a nest. Use care and two fingers. |

|

| Step 21) Install the rear

tender shell by moving the wiring harness off to the right side of the

bar that connects the tender to the engine and mating the tab on the

front of the tender frame with the slot in the tender shell. The tender

frame will slide back into the recess of the lower tender shell and the

fastener hole in the frame should line up with the hole in the rear of

the tender shell. Use the same care as shown above. There is no

"snap in place" situation here and if it is not freely lining

up check the wire harness and alignment for binding or the front slot

will break in the tender shell under force. Capture the original threads

as defined above. |

|

| Step 22) Now that it is all together

lets check the trucks to see

if they are twisted. Objective is to have all four wheels touching the

track on both trucks at the same time all of the time. Place a couple

sections of straight track together on your bench and place the

locomotive on them. View the spacing at the point where the wheels meet

the track as you slowly tilt the tender away from you. Each pair should

leave the track at the same time and contact the track at the same time

when unit is returned. If they do not touch at the same time the truck

is twisted and needs to be straightened. Remove the train, use slight

finger pressure by twisting the trucks opposite direction holding both

frames of the truck. Do not put twisting pressure on the rivits or you

will need to redo Step 10. Twist a little, check a lot. They bend

easily. If wheel pair is not touching at all or very little, the side

frame may be bent up or other truck frame may be bend down. Repeat on

the other truck and the other side. When all four pair touch and move

within the frame slots the same amount you are done. Give it a try. If

still issues the problem may be in the motor or e-unit with spring

pressures or worn or burned brushes. |

|

![]()