Early Spreaders

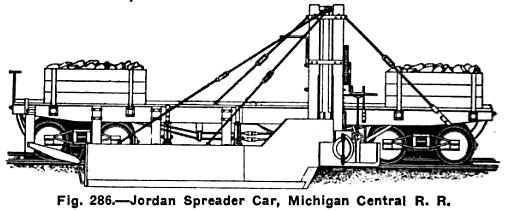

The very first Jordan Spreaders were fairly crude machines.

Patented in 1890, the first Jordans were mostly wood construction, with large ballast boxes on each end. These machines

used manually powered wings, raised and lowered with a gear and rack system. Each wing was 22 1/2' long, and had a fixed spread angle

That is all these spreaders were, spreaders as they did not have any nose plows yet. The first Air powered spreaders were built for the Grand

Trunk Western, the only air operated portion was the raising and lowering of the wing, and only one at a time could be operated by means

of a single air cylinder attached to a cable. It is unknown how many of these original spreaders were built

First Revisions

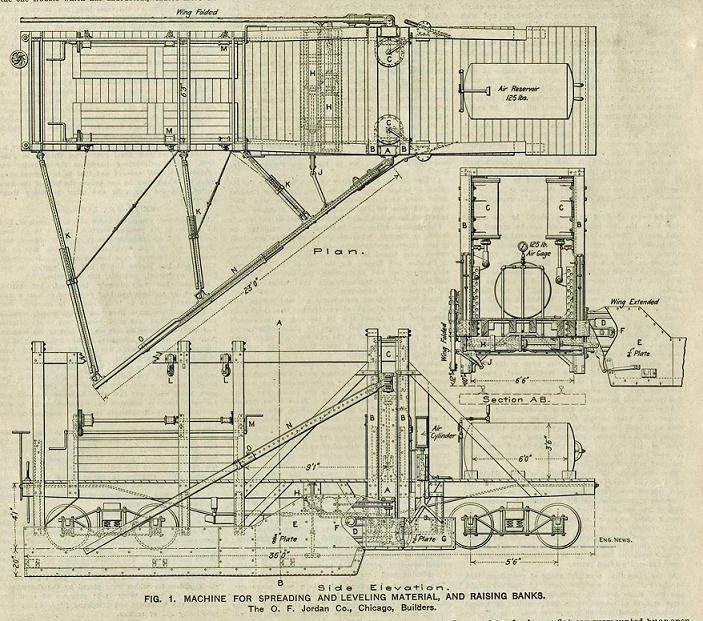

The first major revision was the introduction of penuematic cylinders. On these new Jordans, the wing opening and closing as well as

the verticle movement of the wings were now air powered. The wings now also had a means of control. The spread angle could be adjusted (still

a labor intensive, manual operation). These large steel braces were manually lowered into place using a chain system hung from an overhead

wooden frame. The diagonal brace also offered a means of adjustment, in the same mannor as the wing braces. These original spreaders were

built by an outside shop, some of which were constructed by Hicks Car Works. It is unknown how many of these "box kite" style spreaders were built.

Currently one of which remains, Canadian Pacific 402818 at the Bytown Railway Society. Some of these spreaders were modified with nose blades,

Jordans next great accomplishment.

Knuckle Braced Spreaders

These spreaders were the first commonly used type of Jordan. They were called Knuckle Braced machines as they used a new type of wing brace, that was articulated in the center, acting like a knuckle. To change the spread angle though, one still had to unbolt the braces, and telescope them in or out. This spreader featured an all steel construction, and a nose plow. This nose plow was raised and lowered vertically for use in spreading ballast and light snow removal, as well as ripping ice when the ice cutters were installed. The original models featured a fixed diagonal brace. In 1919 a 12" air cylinder was added, allowing quick, in cab control of the diagonal brace. Some early literature have referenced this as a Model A (not to be confused with the Type A). This line of spreaders used air cylinders to provide vertical movement to the nose plow, wing opening cylinders, vertical post cylinders and the diagonal braces (post 1919).

At the same time as the diagonal brace was made pneumatic, a new attachment was added, the "Bank Builder & Ditcher". This was a

movable piece on the rear end of the wing used for making different cut angles in ditching, and spreading snow. Also new, used in

conjunction with the bank sloper was the carry wing. This swung the bank sloper forward to a brace (mounted on front framework) and was

used to make a pocket to carry fill and ballast and fill. Until the late 1920s, setting up the bank sloper and its working angle was still

a manual operation, until an air cylinder was mounted on top of the wing to control it. Two more options on this model were the ditch

casting, a steel casting made specific to a railroads contour, that was bolted to the bottom of the wing, and the trench digger, used in

export machines for digging a small trench to lay cable and such. Information on all these parts and attachments can be seen on other pages of this website.

Many railroads liked to customize these models with cabs of their choice and some home built options. Later on Jordan offered major rebuild

programs for this line of spreaders, including be able to completely rebuild them into the Standard series by stretching the frames and adding

new telescopic braces.